GxP regulations—referring to “good practice” guidelines such as Good Manufacturing Practice (GMP), Good Laboratory Practice (GLP), and Good Clinical Practice (GCP)—set the stage for quality assurance and risk management for pharmaceutical, biotechnology, and medical device companies.

A quality management system (QMS) that supports GxP compliance must do more than manage documents or track training. It needs to be configured to enforce regulatory expectations, maintain data integrity, and provide audit-ready transparency at every step of the product lifecycle.

Below is a guide to configuring a QMS for GxP compliance.

1. Start with a Validated System

Validation is the first requirement for GxP compliance. The QMS must be validated to demonstrate that it performs as intended and consistently produces reliable results.

Key validation requirements:

- System-level and process-level validation

- Documented testing protocols and results

- Change control procedures for updates or configuration changes

- Revalidation after significant system changes

A pre-validated QMS reduces the burden on internal teams and accelerates compliance timelines.

2. Enable Secure, Tamper-Evident Audit Trails

GxP guidelines require full traceability of records, actions, and decisions. Every critical activity must be documented and linked to the person performing it.

The QMS should support:

- Automated, time-stamped audit trails for all record creation, modification, and deletion

- Tamper-evident logging

- Clear attribution of user activity

- Long-term audit trail retention

Audit trails must not be alterable by users and should be easily retrievable during inspections.

3. Configure Role-Based Access Controls

Data integrity and security are core components of GxP compliance. The QMS must enforce access controls that prevent unauthorized changes and ensure accountability.

QMS access control features should include:

- Unique user IDs and authentication (e.g., password rules, multi-factor)

- Role-based permissions that limit access to only what’s necessary

- Electronic signature enforcement for critical actions

- Account lockout and expiration controls

Limiting access to system functions helps prevent data manipulation and protects sensitive information.

4. Align Workflows with GxP Processes

The QMS should reflect how your organization manages GxP processes. It must support standardized, documented workflows that meet regulatory expectations.

These workflows typically include:

- Document control and version management

- Training and qualification tracking

- Corrective and Preventive Action (CAPA)

- Deviations and nonconformances

- Change control

- Equipment calibration and maintenance

- Risk management

- Supplier qualification and audits

Each workflow should include review and approval stages, defined responsibilities, and status tracking to ensure consistency and oversight.

5. Maintain Document Control and Versioning

Controlled documents are central to GxP compliance. The QMS must ensure that only the most current, approved versions of procedures, work instructions, and specifications are accessible.

Key document control features include:

- Version control with change history

- Review and approval routing with electronic signatures

- Obsolete document archiving

- Automatic distribution and acknowledgment

- Access restrictions to draft or obsolete versions

The QMS should also support traceability from training records to controlled documents.

6. Track Training and Qualification

GxP regulations require that personnel are trained on current procedures and qualified for their roles. The QMS must include a training management system that links employee training to quality documents.

Essential capabilities include:

- Role-based training assignment

- Automated training notifications

- Tracking of completion status and due dates

- Assessment and qualification tracking

- Retraining triggers upon procedure updates

Training records must be accessible and auditable during inspections.

7. Manage Change Control

Any change to GxP-relevant processes, documents, systems, or equipment must be evaluated for impact and approved before implementation.

The QMS must enable:

- Change request initiation and impact assessment

- Risk analysis and justification documentation

- Review and approval workflows

- Implementation tracking

- Linkage to related documents, training, and validation activities

Effective change control prevents unintended consequences and ensures regulatory traceability.

8. Support Risk Management and CAPA

A GxP-aligned QMS must incorporate tools to manage risk proactively and respond to quality issues systematically.

The QMS should include:

- Risk assessment templates and scoring logic

- Tools to document investigations, root causes, and containment

- CAPA planning, approval, and effectiveness checks

- Links to audits, deviations, or complaints that trigger CAPAs

This integrated approach helps prevent recurrence and supports continuous improvement.

9. Ensure Data Integrity Across Systems

Data integrity is a critical component of GxP. All records must be attributable, legible, contemporaneous, original, and accurate (ALCOA).

To maintain data integrity, the QMS must:

- Automate records where possible

- Prevent unauthorized edits or deletions

- Timestamp all entries

- Link all actions to individuals through secure login

- Support audit logging and retention policies

The QMS must be part of a broader IT infrastructure that enforces these principles across all connected systems.

10. Enable Inspection Readiness and Reporting

During regulatory audits, inspectors expect immediate access to records, audit trails, and documentation of GxP compliance.

The QMS should allow:

- Real-time report generation

- Configurable dashboards for compliance tracking

- Quick retrieval of specific records (e.g., training, CAPAs, change controls)

- Export and printing options for documentation requests

An inspection-ready QMS eliminates delays and shows regulators that the organization is in control of its processes.

From Configuration to a Culture of Quality

Configuring a QMS for GxP compliance requires more than toggling settings. It involves building a system that embeds quality into every step of the product lifecycle, with clear documentation, secure data management, and oversight of every action.

For life sciences companies, choosing a QMS that supports GxP out of the box can reduce compliance risk, speed up validation, and streamline regulatory audits.

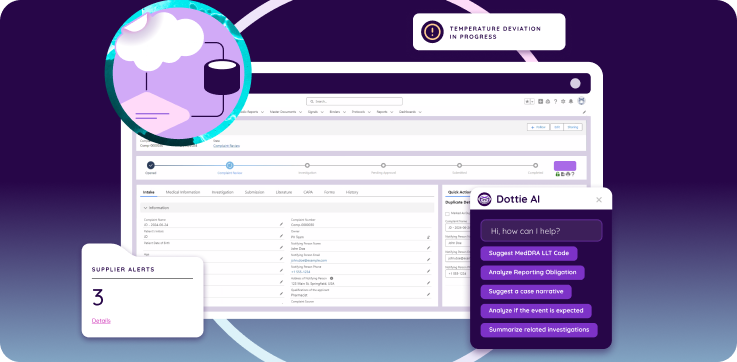

A modern, cloud-based QMS like Dot Compliance can help meet these requirements with validated workflows, built-in controls, and audit-ready transparency.

Schedule a demo to learn how Dot Compliance supports regulatory compliance from day one.