QMS [Quality Management Systems] Explained: Deployment Options, Key Processes and Compliance

Quality is not just a requirement in life sciences. It is what builds trust, ensures patient safety, and keeps products moving to market. Every product, batch, and document reflects an organization’s commitment to doing things right the first time. That commitment is only sustainable when quality processes are organized, traceable, and connected across the entire organization.

Behind every successful company is a system that keeps quality on track—from documentation and training to audits, change management, and risk control. This system is what turns quality from a department into a company-wide culture. It ensures that the right people follow the right procedures at the right time and that every action is recorded, approved, and auditable.

That system is the Quality Management System (QMS).

A QMS is the backbone of compliance and operational excellence in regulated industries such as pharmaceuticals, biotechnology, and medical devices. It defines how an organization plans, executes, and verifies the activities that affect product quality and regulatory compliance. Without a structured QMS, even small errors or gaps in documentation can lead to deviations, recalls, or failed inspections.

As global regulations evolve and technology advances, many companies are moving beyond paper or hybrid systems toward electronic, cloud-based QMS solutions. These digital systems not only simplify compliance but also help organizations improve efficiency, reduce manual effort, and make data-driven decisions.

Whether your goal is to simplify compliance, prepare for inspections, or move from manual to digital processes, understanding how a QMS works is the first step. This guide explains the fundamentals of a QMS, what it is, how it works, the types available, and the standards it supports, so you can determine the right approach for your organization and its stage of growth.

What Is a Quality Management System?

A QMS is a framework of policies, procedures, processes, and records that ensures an organization consistently delivers products and services that meet both customer and regulatory requirements.

For regulated industries like pharma, biotech, medical devices, and cosmetics, a QMS ensures quality, traceability, and compliance.

It creates a single source of truth for all quality activities, from document control and training to CAPA and audits.

A strong QMS standardizes how work gets done, enforces accountability, and captures evidence to support audits, inspections, and continuous improvement.

Why Does a QMS Matter?

A QMS is more than a set of procedures. It is the framework that ensures every part of an organization works toward the same goal: delivering consistent, compliant, and high-quality products. In regulated industries, the QMS is what connects people, processes, and data across the entire product lifecycle.

A well-designed QMS creates structure and accountability. It defines how work gets done, who is responsible for each step, and how every decision is documented. Without this structure, it becomes difficult to maintain control, prove compliance, or respond to issues quickly. With it, companies gain visibility into quality operations and can identify areas for improvement before they turn into problems.

A modern QMS also supports digital transformation. Paper-based systems or scattered spreadsheets make it hard to manage documents, track training, or follow up on CAPAs. A digital QMS brings all these activities into one place. This centralization reduces errors, saves time, and provides a clear audit trail for inspectors or regulators.

1. Ensure Compliance

Compliance is the foundation of quality management. A QMS helps organizations align with global regulations such as FDA 21 CFR Parts 11, 210, 211, and 820, EU Annex 11, ISO 9001, ISO 13485, and other GxP requirements. It enforces documentation standards, approval workflows, and electronic signatures that meet these regulations. By building compliance into daily operations, companies reduce the risk of audit findings and regulatory penalties.

2. Reduce Risk

Every organization faces risk—process deviations, human error, or supplier issues can all affect product quality. A QMS identifies, tracks, and mitigates those risks. It provides tools to document nonconformances, perform root cause analysis, and implement corrective and preventive actions (CAPAs). Early identification and documentation of risks help organizations respond quickly and prevent recurrence. Over time, this creates a more predictable and reliable operation.

3. Increase Efficiency

A QMS eliminates redundant work and manual processes. Automated workflows ensure that documents move through review and approval without delays. Notifications and reminders keep tasks on track. Training is automatically assigned when procedures change. This automation reduces administrative burden and frees teams to focus on higher-value activities like process improvement and innovation.

4. Build Trust

Customers, regulators, and partners all expect transparency. A QMS gives organizations the ability to show complete traceability, from the creation of a document to the release of a product. This visibility builds confidence that quality is not an afterthought but an integrated part of the business. Companies with reliable QMS processes are also more likely to build long-term relationships with customers and regulatory agencies.

5. Drive Improvement

Quality management is not static. A QMS enables organizations to collect data, monitor performance, and identify trends. Dashboards and reports turn information into actionable insight, helping teams focus on areas that need attention. Continuous improvement becomes measurable, not just a goal.

A strong QMS is not just about passing audits. It is about creating a culture where quality drives performance, efficiency, and trust. In every department (from R&D to manufacturing to post-market) quality becomes everyone’s responsibility, supported by a system that makes it possible to deliver consistently high standards.

What Are the Main QMS Standards?

Every QMS helps organizations deliver consistent, compliant, and high-quality products. While the core principles of quality management, such as process control, accountability, and continuous improvement, apply to all industries, the standards that define a QMS vary by sector and geography. These standards set the foundation for how companies document, execute, and verify their quality processes.

A strong QMS aligns with one or more of these frameworks to meet regulatory expectations and drive operational excellence. Below are the key standards that shape quality management across life sciences and other regulated industries.

1. ISO 9001: Quality Management for All Industries

ISO 9001 is the most widely used quality management standard in the world. It applies to any organization, regardless of size or industry, and focuses on establishing a consistent approach to quality through documented processes and measurable improvement.

The standard emphasizes seven core principles: customer focus, leadership, engagement of people, process approach, improvement, evidence-based decision-making, and relationship management.

For life sciences companies, ISO 9001 often serves as the foundation for more specialized frameworks such as ISO 13485 or FDA 21 CFR Part 820.

2. ISO 13485: Quality Management for Medical Devices

ISO 13485 builds on ISO 9001 and adapts its requirements for the medical device industry. It focuses on product safety, regulatory compliance, and risk management across the product lifecycle. Compliance with ISO 13485 demonstrates that a company maintains a documented, effective system for design control, supplier management, traceability, and complaint handling. It also aligns closely with FDA 21 CFR Part 820 and its upcoming replacement, the QMSR (Quality Management System Regulation), making it a recognized global benchmark for medical device quality systems.

3. ISO 14971: Risk Management for Medical Devices

ISO 14971 provides a framework for identifying, assessing, and controlling risks associated with medical devices. This standard focuses specifically on product-related risks, guiding manufacturers to evaluate potential hazards, estimate their probability and impact, and apply effective risk controls.

Integrating ISO 14971 within a QMS ensures that risk management remains continuous from design through production and post-market activities.

4. 21 CFR Parts 210 and 211: Pharmaceutical GMP

The U.S. Food and Drug Administration (FDA) defines current Good Manufacturing Practices (cGMP) for drugs in 21 CFR Parts 210 and 211. These regulations establish the minimum requirements for how pharmaceuticals are produced, controlled, and documented to ensure identity, strength, quality, and purity. A QMS that follows cGMP ensures that all manufacturing steps, from raw materials to finished product, are performed according to approved, validated processes. It also ensures that deviations are tracked, investigated, and resolved with proper documentation.

5. 21 CFR Part 820: Quality Management System Regulation (QMSR)

21 CFR Part 820 establishes quality system requirements for medical device manufacturers. It covers design controls, production, CAPA, complaint handling, and recordkeeping.

The upcoming shift from QSR to QMSR is intended to align FDA expectations more closely with ISO 13485, creating consistency between U.S. and international medical device quality standards.

6. 21 CFR Part 11 and EU Annex 11: Electronic Records and Signatures

As quality systems transition from paper to digital environments, compliance with 21 CFR Part 11 (U.S.) and EU Annex 11 (Europe) is critical. These regulations define how electronic records and signatures must be managed to ensure authenticity, integrity, and security.

They set requirements for user access, audit trails, validation, and long-term data retention. Any electronic QMS (eQMS) must comply with these regulations to be accepted by regulators.

7. Modern QMS Software and Regulatory Alignment

Modern QMS software simplifies compliance by embedding these regulatory standards directly into the platform. Dot Compliance’s Salesforce-native QMS solution is pre-aligned with FDA, ISO, and EU standards, offering built-in audit trails, secure electronic signatures, and pre-validated implementation packages. This approach reduces deployment time, minimizes validation costs, and ensures continuous compliance across the enterprise.

By aligning with these standards, organizations establish a strong foundation for regulatory readiness, operational consistency, and product quality. An effective QMS is not only about meeting compliance; it is about creating a system that supports safe, efficient, and scalable operations worldwide.

Modern QMS solutions, like Dot Compliance’s Salesforce-native eQMS, are pre-aligned with these standards and come with validation packages to reduce deployment time and cost.

What Are the Different Types of QMS Solutions?

Organizations can implement a QMS in different ways depending on their digital maturity, budget, and regulatory requirements. The right approach depends on how centralized, automated, and scalable their processes need to be.

1. Manual or Paper-Based QMS

A paper-based QMS is often the starting point for smaller companies or early-stage organizations. It relies on printed SOPs, forms, binders, and manual signatures. While it requires minimal upfront investment, it also introduces significant limitations.

Paper systems are slow to update, difficult to audit, and prone to human error. Version control is nearly impossible to maintain, which means teams often work with outdated documents. When changes are made, distribution is manual, and training records can easily be lost or misplaced.

During audits, retrieving documents becomes time-consuming, creating compliance risks. Paper systems can meet basic regulatory needs, but they lack the traceability, efficiency, and oversight needed for sustained compliance in highly regulated industries.

2. Hybrid QMS

A hybrid QMS combines some digital tools, such as shared drives or document repositories, with manual processes. Many organizations transition to this model as they begin to digitize their operations. While it improves accessibility and reduces physical paperwork, it still lacks automation, audit trails, and standardized workflows.

Hybrid systems often depend on spreadsheets or email-based approvals, which leads to inconsistent version control and limited accountability. Without true integration, data remains siloed between departments. This structure can be a temporary solution, but as the organization grows, it quickly becomes inefficient.

3. Legacy On-Premises QMS

Legacy on-premises systems were once the standard for regulated industries. These systems are installed on company servers and managed by internal IT teams. They offer a degree of control but come with high maintenance costs, hardware dependencies, and limited scalability.

Every upgrade or change requires validation, testing, and often weeks of downtime. Remote access is restricted, making collaboration between teams or global sites difficult. As regulations evolve, these systems can become rigid and costly to maintain.

While legacy systems may still support compliance, they often hinder innovation. For many organizations, the move to the cloud is no longer optional but necessary to stay competitive and flexible.

4. Cloud-Based eQMS

A cloud-based QMS offers the control of an on-premises system with the flexibility and scalability of the cloud. It centralizes data, automates workflows, and provides real-time access from anywhere.

Teams can collaborate globally while maintaining compliance with FDA, EMA, and ISO requirements. Automated version control, approval routing, and training assignments ensure that every process remains traceable and compliant.

Security and validation are built in, with vendors providing pre-validated solutions and continuous updates that meet regulatory expectations. Cloud-based systems reduce IT burden, eliminate the need for local servers, and deliver faster implementation.

Dot Compliance delivers a Salesforce-native, pre-validated QMS that connects all core quality processes, including Document Management, CAPA, Change Control, Risk, and Training into one secure platform.

5. AI-Enabled eQMS

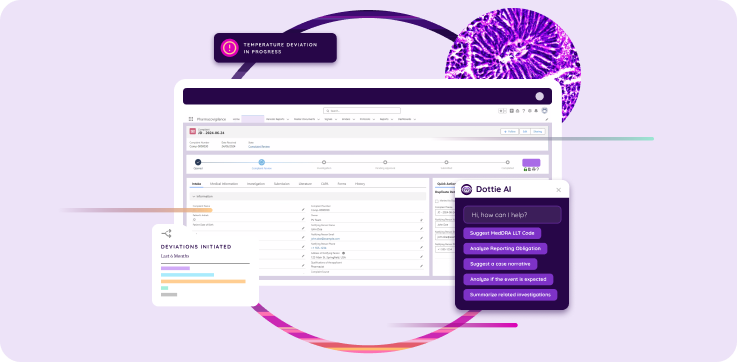

The next stage in QMS evolution is the integration of artificial intelligence. An AI-powered QMS goes beyond automation by using data-driven intelligence to detect anomalies, identify trends, and predict potential risks before they occur.

AI capabilities enable smarter search, faster analysis, and more informed decision-making. Quality teams can use AI insights to prioritize CAPAs, anticipate compliance gaps, and continuously optimize performance.

Dot Compliance’s Dottie AI introduces conversational analytics and governed intelligence to daily quality operations. Users can interact with the system naturally to find information, analyze data, and manage risks in real time. By combining automation with AI, organizations gain both efficiency and foresight, transforming quality from a reactive function into a proactive advantage.

Choosing the Right QMS for Your Organization

Selecting the right deployment option depends on several factors: regulatory complexity, company size, geographic footprint, and long-term growth plans.

- Small companies may start with a simple system but should plan for scalability as they expand.

- Global organizations with multiple sites or products benefit most from cloud-based or AI-powered systems that deliver real-time collaboration and visibility.

- Companies modernizing from legacy platforms can reduce risk and deployment time with pre-validated, ready-to-use eQMS solutions like Dot Compliance.

No matter where an organization begins, the goal remains the same: to establish a QMS that ensures compliance, strengthens control, and supports continuous improvement.

What Documentation Belongs in a QMS?

A QMS relies on accurate, controlled, and traceable documentation. Every activity within quality, manufacturing, and compliance processes depends on documents that define expectations, guide execution, and capture evidence of completion. Without proper documentation, even the most sophisticated system cannot prove compliance or consistency.

Effective documentation ensures that employees follow standardized procedures, regulators can verify compliance, and organizations can trace every change, approval, and result. Below are the most common categories of QMS documentation and how each supports quality and compliance.

1. Policies: Define Intent and Governance

Policies establish the organization’s commitment to quality and define the framework that guides decision-making. They describe the intent behind the QMS, outline responsibilities, and set the direction for how compliance is managed. For example, a Quality Policy may define the organization’s dedication to meeting regulatory requirements and maintaining continuous improvement. Clear policies ensure alignment across departments and provide leadership accountability.

2. Procedures / Standard Operating Procedures (SOPs): Describe How Processes Are Executed

Procedures, often referred to as SOPs, describe how specific processes are performed. They translate policies into actionable steps, ensuring that activities such as training, document control, or corrective actions are completed consistently. SOPs must be written in a clear, structured format and reviewed regularly to ensure they reflect current practices. They are the backbone of operational consistency and a key component of inspection readiness.

3. Work Instructions: Guide Task-Level Details

Work Instructions provide detailed, step-by-step guidance for specific tasks within a process. They are often more granular than SOPs and are used by operators, technicians, or quality staff to ensure accuracy in daily work. For example, a work instruction might describe exactly how to calibrate a piece of equipment or perform a visual inspection. These instructions minimize variability and support compliance by ensuring repeatability.

4. Forms and Templates: Standardize Data Entry

Forms and templates ensure that data is collected in a consistent, structured way. They define what information needs to be captured, how it should be formatted, and who should complete it. Consistent use of standardized forms reduces errors, improves traceability, and simplifies reporting. Examples include CAPA forms, deviation reports, or training records.

5. Records: Capture Execution and Results

Records serve as the evidence that a process was followed and completed. They document the results of actions taken, such as production runs, audits, inspections, and training sessions. Records must be accurate, legible, and stored securely. They are essential for demonstrating compliance during audits and inspections and for investigating nonconformances or quality events.

6. Change Records: Show Approvals, Implementation, and Verification

Change Records track modifications made to documents, processes, or systems. They show who approved the change, when it was implemented, and how it was verified. This ensures that all updates are intentional, reviewed, and properly authorized. Maintaining complete change records is critical for traceability and for demonstrating that change control procedures are followed consistently.

7. Training and Validation Documentation: Prove Competence and Control

Training and validation records confirm that employees are qualified to perform their assigned tasks and that systems or processes operate as intended. Training records show that personnel have read, understood, and applied relevant procedures. Validation documentation demonstrates that computerized systems, equipment, and processes meet defined specifications and perform reliably. Both are required to maintain compliance with regulations such as FDA 21 CFR Part 11 and ISO 9001.

8. Digital Document Management Systems (DMS)

A digital Document Management System brings all these document types together in one controlled environment. It ensures version control, automated approval routing, secure access, and complete audit trails. Users can easily find the latest approved versions, receive notifications of required training, and confirm completion. A DMS also simplifies updates and eliminates the risks of paper-based systems, such as lost records or outdated SOPs in circulation.

Modern QMS software, such as Dot Compliance’s Salesforce-native eQMS, integrates document management with other quality processes like CAPA, change control, and audit management. This creates full traceability from policy creation through implementation and verification. By digitizing documentation, organizations strengthen data integrity, improve inspection readiness, and maintain control across global operations.

What Are the Core QMS Processes?

A modern QMS connects all quality operations into one traceable, controlled environment. These processes work together to ensure compliance, efficiency, and continuous improvement across the entire organization.

1. Document Management

Document management is the foundation of every QMS. It controls how policies, procedures, SOPs, and records are created, reviewed, approved, and distributed. A digital document management process ensures version control, prevents unauthorized edits, and provides full traceability of changes. With automated workflows and electronic signatures, teams can access the right document at the right time, reducing compliance risk and improving efficiency.

2. Training Management

Training management ensures that every employee is qualified to perform their assigned tasks. A QMS links training records directly to controlled documents and SOPs so that when a document is updated, related training requirements are automatically triggered. This connection guarantees that employees always work according to the latest procedures and that compliance evidence is ready for audits or inspections.

3. Change Management

Change management governs how modifications to processes, equipment, documents, or systems are evaluated and implemented. It ensures that every change is reviewed for risk, approved by the right stakeholders, and properly verified before going live. Automated workflows within a QMS reduce delays, enforce accountability, and maintain regulatory control throughout the lifecycle of a change.

4. Quality Event Management

Quality event management provides a centralized process for capturing and investigating deviations, nonconformances, or other quality incidents. A QMS standardizes event reporting, root-cause analysis, and corrective actions to ensure consistency across departments and sites. This proactive approach helps identify systemic issues early and prevent recurrence.

5. CAPA Management

Corrective and Preventive Action (CAPA) management is a critical process for continuous improvement. It enables teams to investigate issues, determine root causes, and implement corrective and preventive steps. A connected QMS links CAPAs to related quality events, audits, or complaints, ensuring complete traceability and effectiveness verification. Automated tracking and reporting also make it easy to demonstrate compliance during inspections.

6. Complaint Management

Complaint management ensures that customer and product complaints are captured, evaluated, and resolved in a consistent, compliant way. A QMS automates complaint intake, categorization, investigation, and closure while maintaining clear links to CAPAs and risk assessments. This process not only meets regulatory expectations but also strengthens product quality and customer satisfaction.

7. Audit Management

Audit management supports both internal and external audits by planning, executing, and tracking audit activities. A QMS automates scheduling, checklists, and follow-ups while maintaining a complete history of findings and responses. Centralized visibility allows quality teams to monitor audit readiness and ensure timely closure of findings across the organization.

8. Risk Management

Risk management is integrated throughout all QMS processes to identify, assess, and mitigate potential quality or compliance risks. A QMS provides structured risk assessment tools, such as FMEA or risk matrices, to evaluate impact and likelihood. Continuous monitoring of risk trends enables better decision-making and supports regulatory expectations under standards like ISO 14971 and ICH Q9.

9. Supplier Quality Management

Supplier quality management ensures that all external partners—such as contract manufacturers, testing labs, and raw material providers—meet defined quality standards. A QMS centralizes supplier qualification, audits, and performance tracking. By maintaining visibility into supplier activities, organizations can reduce supply-chain risk and ensure product quality across global operations.

10. Electronic Batch Records (EBR)

Electronic Batch Records (EBR) streamline manufacturing documentation by capturing all production data digitally. A QMS with EBR functionality ensures that every batch is produced according to approved specifications and that data integrity is maintained throughout the process. Automating batch record review and approval accelerates product release, minimizes errors, and supports compliance with cGMP and FDA regulations.

These processes are interconnected. A deviation might trigger a CAPA, which results in document updates and training assignments, all automatically linked for traceability.

What Industries Benefit Most from QMS Software?

While quality management applies to every organization, its impact is most significant in regulated industries where compliance, traceability, and documentation are essential. Modern QMS software provides the structure and control needed to meet these demands, reduce risk, and ensure that operations align with global regulatory standards.

1. Pharmaceutical

Pharmaceutical manufacturers operate in one of the most highly regulated industries in the world. A Quality Management System (QMS) supports compliance with Good Manufacturing Practices (GMP) and helps ensure that products meet safety and efficacy requirements.

By digitizing and automating batch records, document approvals, and deviation tracking, a QMS allows companies to maintain traceability throughout the entire product lifecycle. This transparency is critical during audits and inspections, where regulators expect quick access to records and data integrity proof.

A connected QMS also improves efficiency by reducing manual errors, accelerating product release cycles, and maintaining continuous inspection readiness. For organizations navigating complex regulatory requirements like 21 CFR Parts 210/211, digital tools make compliance an integral part of daily operations.

2. Biotechnology

Biotechnology companies face unique challenges as they move from discovery to clinical trials and ultimately to commercial production. Maintaining compliance during this transition requires strict process control, document traceability, and alignment with GxP and ISO standards.

A QMS helps biotech organizations manage R&D documentation, control protocols, and maintain oversight as teams grow and collaborate across multiple locations. It ensures version control, streamlines approvals, and provides real-time visibility into studies, experiments, and validations.

By automating document and training management, biotech companies can accelerate innovation while ensuring compliance with regulatory expectations from agencies such as the FDA and EMA.

3. Medical Device

Medical device manufacturers must meet the stringent requirements of ISO 13485, ISO 14971, and FDA 21 CFR Part 820 (soon to become the QMSR). A QMS provides the framework for managing design controls, risk assessments, CAPA, and complaint handling.

Integrated electronic workflows enable teams to link design history files (DHF), device master records (DMR), and production records, ensuring complete traceability from design to market release.

With the rise of post-market surveillance requirements, a QMS also supports continuous monitoring of device performance, complaint resolution, and regulatory reporting. This helps manufacturers maintain compliance and safeguard patient safety.

4. Cosmetics

Cosmetics manufacturers face increasing global regulation under frameworks such as the EU Cosmetics Regulation (EC) No 1223/2009 and the U.S. Modernization of Cosmetics Regulation Act (MoCRA).

A QMS enables full ingredient traceability, manages supplier quality, and ensures consistent product formulation across global supply chains. Automated document management keeps product information files (PIFs) current and accessible for regulatory review.

By managing training, change control, and deviation tracking in one platform, cosmetic companies can maintain brand integrity while meeting safety and labeling requirements in multiple markets.

5. Clinical Research

Clinical research organizations (CROs) and sponsors rely on QMS software to ensure compliance with Good Clinical Practice (GCP) standards. The system helps maintain SOPs, manage investigator training, and ensure readiness for audits and inspections.

Centralized document control allows teams to manage trial master files (TMFs), version histories, and approval workflows efficiently. Real-time access and audit trails improve visibility for both CROs and sponsors, reducing risk across multi-site studies.

6. Contract Manufacturers and Suppliers

Contract manufacturers (CMOs) and contract development and manufacturing organizations (CDMOs) operate in highly collaborative environments that require strong oversight of suppliers, materials, and production.

A QMS supports supplier qualification, audit scheduling, and deviation tracking across multiple sites. It provides unified visibility into production processes, enabling consistent quality management between clients and partners.

By integrating electronic batch records, CAPA, and complaint management, QMS software helps contract manufacturers maintain compliance with customer and regulatory requirements, improving trust and transparency across the supply chain.

Driving Quality Across the Value Chain

From pharmaceutical and biotech innovators to device makers and contract manufacturers, QMS software enables organizations to operate with control, traceability, and confidence. Modern systems such as Dot Compliance’s Salesforce-native eQMS bring together document management, training, change control, and audit readiness in one connected environment. The result is faster compliance, reduced risk, and consistent quality across every stage of development and production.

How Does a QMS Support Audits and Continuous Improvement?

A QMS does more than maintain compliance. It creates the foundation for operational visibility, accountability, and ongoing improvement. By centralizing documentation, automating processes, and providing real-time analytics, a QMS helps organizations stay audit-ready at all times and continuously improve quality performance.

1. Audit Readiness

Audits are a constant requirement for regulated organizations, whether internal, external, or regulatory. Preparing for them can be time-consuming when data and records are scattered across departments. A QMS eliminates this challenge by storing all quality data, documents, and records in a single, traceable system.

With centralized access, teams can retrieve complete, approved records within seconds instead of searching through paper files or disconnected systems. This includes training documentation, deviation reports, CAPA records, risk assessments, and equipment logs, all linked to the relevant process or product.

Electronic audit trails record every change, user action, and approval, providing verifiable evidence of compliance with FDA 21 CFR Part 11 and EU Annex 11. By ensuring that only authorized users can make changes and every activity is timestamped, a QMS maintains data integrity and transparency.

This level of control allows organizations to demonstrate compliance at any time, not just in preparation for an inspection. Audit readiness becomes an ongoing state rather than a last-minute effort.

2. CAPA Effectiveness

Corrective and Preventive Action (CAPA) management is one of the most important components of a QMS. When deviations, complaints, or audit findings occur, the system helps identify the root cause, implement corrective actions, and verify effectiveness.

A modern QMS streamlines this process with configurable workflows that guide teams through each stage, from issue identification and investigation to corrective action and closure. Integrated data allows quality teams to analyze trends, uncover recurring issues, and take preventive action before problems escalate.

Root-cause analysis tools within the QMS make it easier to identify systemic weaknesses rather than addressing isolated incidents. This improves CAPA effectiveness, reduces repeat deviations, and strengthens process reliability. Over time, CAPA data also becomes a key source of insight for process improvement and risk management.

3. Continuous Improvement

Continuous improvement depends on accurate, real-time visibility into performance. A QMS provides this visibility through dashboards and key performance indicators (KPIs) that track process trends, audit results, and CAPA metrics.

By monitoring these indicators, organizations can identify bottlenecks, inefficiencies, or areas that need additional training or resources. For example, dashboards may reveal longer approval times in change management or recurring deviations in production. These insights enable proactive decision-making and process optimization.

With integrated analytics and configurable reports, leaders can assess quality performance across sites, products, and departments. Continuous monitoring of quality data also supports management review requirements under ISO 9001, ISO 13485, and FDA QMSR, ensuring decisions are based on objective evidence.

4. Data-Driven Quality with Dot Compliance

Dot Compliance’s QMS provides built-in reporting, analytics, and AI-driven insights that transform quality data into actionable intelligence. The system connects processes such as CAPA, audit management, and change control within one platform, enabling full traceability and faster response times.

By automating data collection and integrating analytics across quality processes, Dot Compliance helps organizations move from reactive issue management to proactive continuous improvement. This strengthens compliance, enhances efficiency, and builds a culture of accountability that supports long-term success.

How Do Dot Compliance Solutions Map to Quality Maturity?

Dot Compliance offers three key tiers of QMS capability:

eQMS Xpress

A ready-to-deploy foundation covering Document, Training, CAPA, Change, and Audit Management. Pre-validated and built on Salesforce for rapid implementation.

Compliance Xpand

Expands to cross-functional quality and compliance areas like Electronic Batch Records, Design Control, Clinical Management, and Regulatory Management, supporting enterprise-wide harmonization.

AI Xpert

Leverages AI for proactive quality management, predictive insights, and governed intelligence across your enterprise.

What Makes Dot Compliance Different?

Dot Compliance combines AI innovation, Salesforce-native architecture, and pre-validated deployment to deliver rapid time to value and sustained compliance.

Key advantages include:

- Fast deployment and low validation burden

- Configurable, scalable modules

- Governed AI for quality and compliance

- Global access and collaboration

- Alignment with ISO, FDA, and GxP standards

Why a Modern QMS Matters

A modern QMS is more than a compliance tool. It is a framework that drives control, visibility, and agility across your organization. As regulatory expectations grow more complex and markets demand faster delivery, relying on manual processes or disconnected legacy systems can hold your business back. A connected, cloud-based QMS gives your teams the ability to adapt quickly, make informed decisions, and maintain product quality with confidence.

Control and Consistency

In today’s competitive and highly regulated environment, maintaining control over processes, documentation, and data is essential. A modern QMS ensures that every document, workflow, and approval follows a structured, validated process. This level of control reduces variability, minimizes human error, and ensures that only the most current, approved procedures are in use.

By managing training, change control, CAPA, and risk management in one platform, quality teams can see how each process connects to the next. When a change occurs, the QMS automatically triggers related updates, training requirements, and approvals. This interconnected control ensures that nothing is overlooked and that every step in production and quality assurance aligns with regulatory expectations.

Visibility Across Operations

Legacy systems often create data silos that prevent teams from seeing the full picture of quality performance. A modern QMS provides centralized visibility into every quality activity, from document status to CAPA progress to supplier performance. Real-time dashboards and analytics allow leadership to track performance indicators across departments, sites, and regions.

This level of transparency supports faster, more confident decision-making. If a deviation occurs, teams can identify the cause immediately and take action to prevent recurrence. During audits, the ability to retrieve complete, verified records within seconds demonstrates compliance and builds trust with regulators and customers.

Agility to Adapt and Scale

The life sciences industry continues to evolve rapidly. Regulatory updates, market changes, and product innovations all require a system that can adapt without disrupting operations. A modern QMS built on a scalable cloud platform provides that flexibility.

Organizations can configure workflows, add new modules, or integrate with other enterprise systems as their needs grow. This adaptability allows startups, mid-sized companies, and global enterprises alike to scale their quality management operations without starting over.

A cloud-based architecture also enables secure remote access, supporting distributed teams and global collaboration. Users can log in from any location, review documents, complete training, and approve changes in real time.

The Role of AI in Modern Quality Management

Artificial intelligence is reshaping the way organizations manage quality. AI-enabled QMS solutions such as Dot Compliance’s Salesforce-native eQMS bring intelligence and automation into daily workflows.

By analyzing quality data, identifying anomalies, and predicting potential risks, AI helps teams act before issues escalate. Automated document reviews, audit readiness checks, and root-cause analysis improve efficiency while ensuring compliance. AI also reduces the burden of repetitive manual tasks, freeing quality teams to focus on strategic initiatives that drive continuous improvement.

The Benefits of Moving Beyond Manual Processes

Manual systems and spreadsheets might work for small operations, but they quickly become barriers as an organization scales. Errors multiply, visibility decreases, and compliance risks increase. A digital QMS eliminates these challenges by ensuring traceability, accountability, and data integrity across every process.

Implementing a connected, AI-powered QMS can:

- Reduce audit preparation time and improve inspection outcomes.

- Shorten approval cycles and accelerate product release.

- Lower operational costs through automation and standardization.

- Improve collaboration across departments and global sites.

- Enable proactive risk management and continuous improvement.

Building a Foundation for the Future

A modern QMS is not just a system upgrade; it is an investment in the future of your organization. It lays the groundwork for long-term compliance, operational excellence, and innovation. As regulatory frameworks expand to include AI governance, data integrity, and sustainability, a flexible and intelligent QMS will allow your organization to adapt with confidence.

By consolidating processes, connecting data, and embedding intelligence into everyday tasks, your teams gain the insight needed to operate efficiently and stay ahead of evolving regulations. Whether your goal is to modernize a legacy system, streamline audits, or prepare for AI-driven quality management, the right QMS can help you achieve it.

Experience the Power of an AI-Powered eQMS

If you are ready to move beyond manual processes and disconnected tools, now is the time to consider a connected, cloud-based approach to quality.

An AI-powered eQMS helps your organization accelerate compliance, reduce risk, and simplify quality management.

Contact us to schedule a demo and discover how Dot Compliance can help your organization accelerate compliance, reduce risk, and simplify quality management.