What KPIs Should Executives Track in Their QMS?

An effective Quality Management System (QMS) is a source of critical business intelligence. For executives, it’s essential to track Key Performance Indicators (KPIs) that connect quality metrics to high-level business outcomes like cost, risk, and efficiency. By monitoring the right QMS data, leaders can make informed, strategic decisions that drive performance.

KPIs for Operational Efficiency and Cost

These metrics measure how efficiently your quality processes run and their direct impact on the bottom line.

- Cost of Poor Quality (COPQ): This is one of the most critical KPIs for any executive. COPQ quantifies the financial impact of quality failures. It includes all costs associated with non-conformance, such as scrap, rework, product recalls, and warranty claims. Tracking a consistent reduction in COPQ provides a clear return on investment for your quality initiatives and demonstrates how improving quality directly improves profitability.

- Cycle Time for Quality Processes: This KPI measures the time it takes to complete critical quality workflows, such as resolving a CAPA (Corrective and Preventive Action) or executing a change control. A shorter cycle time indicates an agile and efficient organization. For executives, this means your team can resolve issues faster, implement improvements quicker, and adapt to market changes without being slowed down by internal bureaucracy.

KPIs for Compliance and Risk Management

These indicators provide a high-level view of your organization’s regulatory readiness and its ability to manage risk effectively.

- Number of Recurring Deviations: A single deviation can be an isolated incident, but a recurring one points to a systemic failure. Tracking the rate of repeat non-conformances reveals how effectively your CAPA process solves root causes. A downward trend in this KPI gives executives confidence that the organization is learning from its mistakes and strengthening its processes, which reduces long-term compliance risk.

- On-Time Audit Response Rate: During a regulatory inspection or an audit, the ability to produce requested documents and records quickly is crucial. This KPI measures the percentage of requests fulfilled on time and without issue. A high rate indicates a well-organized, audit-ready QMS and a low risk of receiving negative findings due to poor documentation practices.

KPIs for Product Quality and Customer Satisfaction

These metrics link the QMS directly to your product’s performance in the market and its reception by customers.

- Customer Complaint Rate: This is a direct measure of product quality and customer satisfaction. Executives should track this KPI over time, often segmented by product line or region. A declining complaint rate is a strong indicator of improving product quality, while a sudden spike can be an early warning of a significant issue that requires immediate attention.

- Percentage of On-Time Product Release: Quality control can often be a bottleneck that prevents finished products from being shipped. This KPI tracks the percentage of product batches that are reviewed, approved, and released by the quality department according to schedule. A high on-time release rate shows that your quality processes are efficient and effectively supporting the company’s commercial goals by getting products to market without delay.

Making Quality Quantifiable

The KPIs tracked in your QMS should provide more than just operational data; they should offer strategic insights. When executives monitor metrics related to cost, risk, and customer satisfaction, they can effectively guide their organizations to produce higher-quality products, improve financial performance, and build a resilient culture of quality.

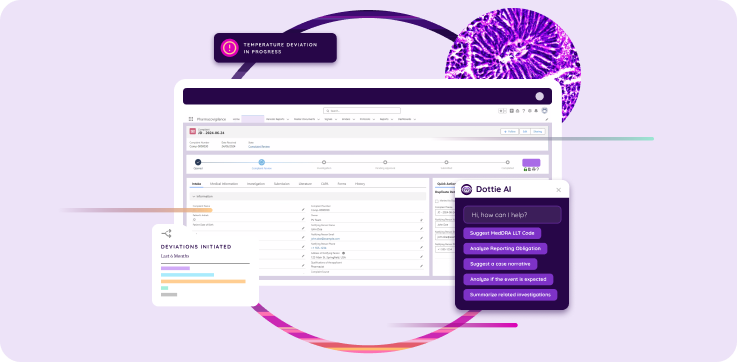

Tracking these KPIs effectively begins with the right platform.

Download our free guide, “How to Choose an eQMS,” to learn how to evaluate a system’s capabilities to ensure you get the visibility you need.