QMS vs eQMS: What’s the Difference and Why It Matters

Quality organizations do not get audited on effort. They get audited on evidence.

Auditors expect documented policies, controlled procedures, and records that prove the organization executes those procedures consistently. That expectation applies across ISO 13485, GMP, FDA expectations, and customer audits. It also applies regardless of company size. Whether an organization operates in one site or twenty, it must show control.

This is where many teams get stuck. They know they need a QMS, but they are not clear on what separates a traditional QMS from an electronic one. They often use the term “QMS” to describe software, even though a QMS can operate without software at all.

To clarify the difference, start here: a QMS defines the quality framework. An eQMS provides the digital platform that runs that framework.

QMS vs eQMS: The Core Difference

A Quality Management System (QMS) is the full set of policies, procedures, roles, controls, and records an organization uses to ensure quality and compliance. A QMS can exist as a paper-based system, a manual system supported by spreadsheets and shared drives, or a legacy on-premises approach built from disconnected tools. In all of these cases, the QMS still exists because the framework exists, even if the execution depends heavily on people and manual recordkeeping.

An electronic Quality Management System (eQMS) is different because it is the software platform used to manage those quality processes digitally. Instead of routing approvals through email, tracking training through spreadsheets, and reconstructing evidence for audits, teams execute quality workflows inside a controlled system that maintains versions, permissions, approvals, and audit trails.

This means the difference is not whether you have a QMS. Most regulated organizations have one.

The difference is whether quality processes operate through manual methods or through a digital platform designed to enforce control.

What Is a QMS?

A QMS is the governance structure behind quality. It defines how teams document work, approve it, train to it, control changes, handle nonconformances, investigate issues, implement corrective actions, and prove effectiveness.

A QMS also includes policy-level decisions. For example, a quality policy may define expectations for documentation control, escalation timelines, CAPA closure requirements, training assignment rules, and approval authority.

These policies shape the organization’s quality culture because they set the standard for what “good” looks like.

The procedures and records follow from that standard.

Because of this, a QMS is not a single tool. It is the operating model for quality.

What Is an eQMS?

An eQMS is the platform that digitizes and enforces the QMS. In practical terms, an eQMS replaces manual routing, manual version control, spreadsheet trackers, and disconnected evidence storage with controlled workflows and structured records.

An eQMS does not remove the need for policies. It puts them into operation.

If the QMS requires that only approved, current SOPs are available at the point of use, the eQMS supports that requirement through controlled document release and automatic versioning. If the QMS requires retraining when documents change, the eQMS supports that requirement by linking documents to training and tracking completion.

In other words, the eQMS turns quality requirements into controlled execution.

Side-by-Side Comparison: Non-Digital QMS vs eQMS

Below is the clearest comparison. It focuses on what most impacts audits, evidence quality, traceability, and scalability.

| Category | Non-Digital QMS (Paper-based, manual, legacy tools) | eQMS (Electronic Quality Management System) |

| Execution method | Manual workflows across paper, email, drives, spreadsheets | Digital workflows in one controlled platform |

| Evidence capture | Manual signatures, inconsistent formats, scanned records | Time-stamped actions and system audit trails |

| Document control | Manual distribution and version tracking | Controlled versioning with approval history |

| Training evidence | Spreadsheet tracking and manual confirmation | Role-based assignments and completion records |

| CAPA and investigations | Template-driven records stored in folders | Structured workflows with linked records |

| Change control | Email routing and offline approvals | Automated routing and impact traceability |

| Traceability | Manual linking across systems and teams | Built-in linkage across related processes |

| Reporting | Manual compilation and inconsistent definitions | Standard dashboards and trends |

| Audit preparation | Reactive evidence chasing | Rapid retrieval through search and reporting |

| Scalability | Breaks down with growth and multiple sites | Supports standardization across sites |

This table highlights what matters most. Manual systems rely on discipline to maintain control.

eQMS systems maintain control through design.

Where the “System” Lives

Teams often believe that if they have SOPs and forms, the system must be “in place.” In reality, the system lives in the execution model.

Non-digital QMS execution

Policies + SOPs exist

→ work happens through human coordination

→ records stored across binders, drives, spreadsheets

→ audit prep depends on assembling proof

eQMS execution

Policies + SOPs exist

→ work happens through controlled workflows

→ records captured automatically in one system

→ audit prep uses search, linked records, and audit trails

Both models can meet minimum documentation expectations. Only one model consistently supports fast audits and scalable execution.

The Limitations of Non-Digital QMS Execution

Non-digital QMS environments do not fail because teams do not care. They fail because manual execution creates too many opportunities for inconsistency. Quality work depends on dozens of handoffs and dependencies, and manual systems make those handoffs fragile.

Version control becomes difficult to enforce

Document control sits at the center of compliance. When documents exist across shared drives or printed binders, organizations rely on employees to locate the correct version and use it. Even with “controlled copies,” teams often discover duplicate files, outdated documents at the point of use, and inconsistent approval evidence. During an audit, the challenge is not simply finding the SOP. The challenge is proving that the organization used the correct version at the correct time and controlled access to obsolete versions.

An eQMS reduces this risk by controlling the lifecycle of documents in one place.

It maintains the approval record, version history, and release state so the organization can demonstrate control without reconstructing the story.

Training records become hard to defend

Manual training tracking often creates audit friction. Many organizations use spreadsheets to track completion, rely on managers for sign-off, and store evidence as scanned PDF files. That approach tends to fracture across departments, especially during growth, site expansion, or turnover. When auditors request training evidence tied to specific SOP versions or roles, teams often spend hours collecting records across systems.

An eQMS improves this by linking training to controlled documents and enforcing assignment logic, completion tracking, and evidence capture in a consistent format.

CAPA becomes slower and less reliable

CAPA is where auditors evaluate whether a QMS drives improvement. Manual CAPA systems frequently depend on templates, shared folders, and trackers maintained by a small number of people. That setup makes it difficult to enforce closure discipline, maintain consistent root cause documentation, track action owners, and complete effectiveness checks on time. It also weakens traceability, since deviations, complaints, and CAPAs often live in different trackers and are only connected through narrative explanations.

eQMS platforms improve CAPA execution by enforcing required steps, maintaining time stamps, and linking CAPA directly to the originating events, changes, and training where needed.

Change control becomes a coordination problem

Change control crosses multiple functions and requires consistent, documented review. In manual environments, teams route change requests through email, record approvals offline, and manage impact assessment in documents. This creates delays, inconsistent review evidence, and gaps between the change record and the documents or training impacted by the change.

An eQMS supports change control through structured routing, approvals, and linkages.

It also strengthens the ability to demonstrate that document updates and training follow from approved changes.

Traceability breaks across disconnected tools

Traceability is one of the most common weaknesses of non-digital systems. Auditors look for clear linkage across complaints, investigations, CAPA, change controls, and training. Manual environments can maintain traceability, but only through disciplined cross-referencing, careful documentation habits, and manual maintenance of links. That approach works until the organization scales or experiences turnover.

eQMS platforms improve traceability by connecting records automatically. They make it easier to show the “why” behind actions and the “proof” behind closure.

The Benefits of Moving to an eQMS

An eQMS improves more than efficiency. It improves the organization’s ability to enforce policy and defend compliance with clear evidence.

Stronger audit readiness

Digital quality platforms maintain evidence continuously. Instead of collecting proof before an audit, teams retrieve it. Document histories, approval records, training completion, CAPA timelines, and change control status remain accessible in a consistent format.

Better control at scale

Manual QMS execution can work in smaller environments, but it becomes difficult to sustain across multiple sites, teams, and product lines. An eQMS supports scalability by standardizing workflows and making expectations consistent regardless of who executes the process.

Improved visibility and decision-making

Quality leaders need visibility into trends, overdue actions, recurring issues, supplier performance, and training compliance. Manual systems can provide some visibility, but usually require manual reporting effort and data cleanup. eQMS platforms support structured reporting that reflects current, consistent data.

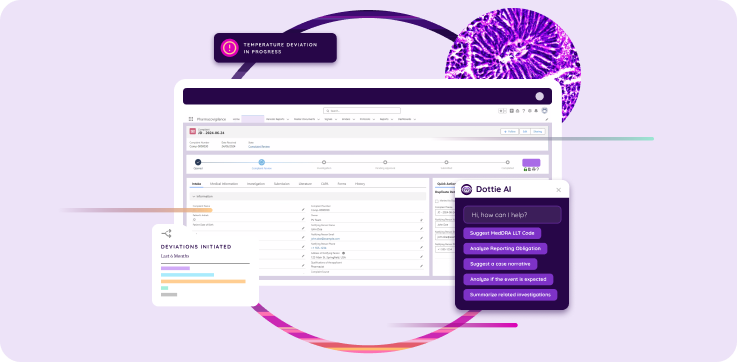

Why eQMS Improves Audit Evidence

eQMS platforms strengthen audit evidence by keeping quality records connected from start to finish. When a quality event is recorded, the system initiates an investigation, links CAPA to the originating issue, and connects any related change controls to the same record trail. As procedures are updated, the eQMS controls version release and assigns retraining to impacted roles, then captures completion as documented proof. The organization can then verify effectiveness and maintain a complete, time-stamped audit trail across every step. Instead of assembling evidence manually for each audit, teams can retrieve the full chain of documentation from one system, with traceability already built in.

When Should a Company Move From a Non-Digital QMS to an eQMS?

Organizations typically evaluate eQMS when manual systems create recurring pain.

Common triggers include:

- Audit prep consumes too much time

- Teams cannot reliably confirm the current SOP at the point of use

- Training evidence takes too long to compile

- CAPAs remain open too long or lack consistent documentation

- Sites follow different processes or maintain separate trackers

- Leadership lacks confidence in quality reporting

These signals usually indicate one issue: the QMS exists, but the execution model no longer supports the organization’s scale.

QMS vs eQMS

A QMS defines your quality framework. It includes policies, procedures, and records that establish control and support compliance. That QMS can operate in manual formats such as binders, shared drives, spreadsheets, and legacy on-premises tools.

An eQMS is the digital platform that executes that same QMS framework electronically. It standardizes workflows, captures audit trails, links records, and supports reporting.

The difference matters because regulated organizations do not only need a QMS. They need a QMS they can enforce consistently and prove under audit without reconstructing evidence manually.

Get a more in depth look at why eQMS is essential in today’s digital landscape. Download the free white paper for more.