Cosmetics QMS [Quality Management System]

Quality in cosmetics is not just a marketing promise. It is the condition for operating in regulated markets. You do not get to develop, manufacture, label, or sell a cosmetic product unless you can show that it is safe for use under normal and reasonably foreseeable conditions. Authorities do not simply look at the final product on a shelf. They look at how you designed it, where you manufactured it, how you controlled contamination and variation, and whether you can prove the product will not harm consumers when used as intended.

Cosmetics are often positioned as lifestyle products, but behind that positioning sits a set of hard expectations. Regulators expect companies to understand what is in their products, where those ingredients came from, how they are controlled, and what level of risk they pose. They expect that every batch is made under clean and orderly conditions. They expect labels to be accurate and complete. They expect that when something goes wrong, the company can trace the issue back, understand what happened, and take action.

That level of control does not come from “good manufacturing habits” alone. It requires structure.

That structure is the Cosmetics Quality Management System.

A Cosmetics Quality Management System (cosmetics QMS) is the framework that defines how a cosmetics company plans, carries out, documents, reviews, and improves all activities that affect product quality and consumer safety. It acts as the operating system for the business. It describes how products move from concept to discontinuation in a controlled way. It connects formulation development, raw material sourcing, manufacturing, filling and packaging, labeling, testing, storage, distribution, complaints, and corrective actions into one coherent system.

A cosmetics QMS is not a few SOPs in a shared folder. It is not a binder that comes out when an auditor arrives. It is not “what the quality group does while everyone else runs the business.” It is a live system that shows people how to do their work, enforces the use of those methods, and produces records that prove work was done as required. It is the network of policies, procedures, work instructions, specifications, safety assessments, batch records, complaints, investigations, and management reviews that allow a company to say, with evidence, “we are in control.”

In a mature cosmetics QMS, this structure does more than avoid citations or warning letters. It supports repeatable production, reliable supplier performance, clean product handoffs between development and manufacturing, structured introduction of new packaging and claims, and faster resolution of issues. It gives leaders a clear view of where risks sit in the operation and where performance is improving or declining. It turns quality from a reactive function into an active input to business decisions.

For many companies, especially fast-growing brands, the default model has been paper, email, spreadsheets, and institutional memory. Formulas live in one system, artwork in another, training records in a shared drive, and complaints in a mailbox. That model can work for a small portfolio and a single geography. It breaks quickly when you add more products, more markets, more contract manufacturers, and more regulatory pressure. At that point, the lack of an integrated QMS stops being a nuisance and becomes a risk.

This is why cosmetics companies of all sizes are moving toward structured, often electronic, QMS platforms. A modern cosmetics eQMS centralizes core processes, automates routing and approvals, enforces version control, and connects sites and partners. It provides the structure regulators expect and the visibility leaders need.

The rest of this guide explains what a cosmetics QMS is, how it fits with regulations and standards, which processes it must control, and why modern, connected platforms are becoming unavoidable for cosmetics manufacturers and brands.

What Is a Cosmetics Quality Management System (QMS)?

A Cosmetics Quality Management System is the documented, implemented, and maintained system that ensures cosmetic products are consistently manufactured to a level of quality and safety that meets regulatory requirements and internal standards. It is a framework that governs how work is done, how decisions are made, and how evidence is captured.

At its core, a cosmetics QMS does five things.

First, it defines how critical work should be carried out. It describes how formulas are created and approved, how raw materials are selected and qualified, how bulk is manufactured, how lines are cleaned between products, how batches are filled and labeled, how samples are taken for testing, and how labels are checked for accuracy. These definitions are not informal. They are documented as procedures, work instructions, and specifications that have been reviewed and approved.

Second, it makes sure that the defined way of working is actually followed. This means linking people’s roles to the procedures they must know and use. It means verifying that personnel are trained on those procedures before they perform the work. It means controlling who can change a document, who can approve a batch record, who can sign off on a label, and who can release a product to market. It means ensuring that equipment is cleaned, maintained, and calibrated on schedule and that the conditions under which products are manufactured and stored are controlled.

Third, it captures proof of execution. Every time a batch is produced, the QMS requires a record of what was done: which raw materials and packaging were used, which lot numbers were involved, which settings were applied, which checks were performed, which test results were obtained, and who signed off. When a line is cleaned, there is a documented record. When a complaint comes in, there is a record of what the consumer reported, how the complaint was handled, and what the outcome was. These records are not optional. They form the backbone of the Product Information File in the EU and the evidence supporting safety substantiation under MoCRA and similar requirements in other markets.

Fourth, it requires regular review of that proof. Quality or another designated function evaluates batch records before release. Complaints are assessed to decide whether they indicate a safety concern. Deviations are reviewed to determine impact on product quality and whether an event merits rework, rejection, or market action. Supplier performance is reviewed to decide whether a supplier remains acceptable or needs corrective action or replacement. Management receives periodic reports on quality and safety performance so they can see the state of the system.

Fifth, it uses what it learns to prevent future issues. The QMS provides the structure for root cause analysis, corrective and preventive actions, and validation of those actions. When recurring contamination is identified, the QMS defines how investigations are conducted, what level of analysis is expected, how decisions are documented, and how new controls are put in place. When labels repeatedly fail checks, the QMS feeds that information into artwork and change control processes. When a supplier is linked to multiple nonconformances, the QMS triggers supplier review or requalification.

A cosmetics QMS spans the entire product lifecycle. It starts with product conception and regulatory classification, continues through development, scale-up, routine manufacturing, packaging and labeling, storage, distribution, and then extends into the market through complaint handling, adverse event evaluation, and ongoing safety monitoring. It governs how changes are introduced at any point in that lifecycle and how products are eventually discontinued or reformulated.

It is also expected to work across all arrangements a company may use. Many cosmetic brands rely on a mix of internal manufacturing and external contract manufacturers, contract packers, and third-party labs. The QMS has to define how responsibilities are split, how information flows, and how oversight is maintained in those relationships. It must ensure that even when work is outsourced, control is not.

Historically, companies have tried to implement this framework using static documents and manual control. Paper SOPs, printed batch records, physical training binders, and informal email chains have been the norm. That approach can technically meet the letter of some requirements, but it is fragile. It relies on individual discipline and memory. It makes trending, analysis, and rapid retrieval difficult. It becomes a liability as soon as volume, complexity, or scrutiny increases.

A well-designed cosmetics QMS moves beyond minimal compliance. It is built to hold up under growth, cross-border expansion, and evolving regulation. It integrates processes so that development, operations, quality, regulatory, supply chain, and marketing are working from the same underlying system rather than each building their own.

Why a Cosmetics QMS Matters

From the outside, cosmetics can look simple. They do not require the same level of clinical data as pharmaceuticals, and in many markets they can be placed on the market without pre-approval from regulators. That can create the illusion that the compliance bar is low. In practice, the bar is different, not lower. The responsibility for safety and quality sits more squarely on the company.

A cosmetics QMS matters because it is the only credible way to show that responsibility is being met.

The first reason is regulatory compliance. Major markets now expect companies to have documented evidence that their products are safe and manufactured under appropriate conditions. In the United States, the Modernization of Cosmetics Regulation Act requires safety substantiation for each cosmetic product, serious adverse event reporting, facility registration, and product listing. The FDA is also moving to establish mandatory GMP requirements for cosmetics. Without a QMS, it is difficult to show how safety substantiation was done, how batches are controlled, how facilities are maintained, and how adverse events are evaluated and reported.

In the European Union, the Cosmetics Regulation requires each product to have a Product Information File that includes a safety assessment, manufacturing information, raw material details, stability data, and other supporting information. It requires that the product be manufactured according to GMP, which is usually interpreted as alignment with ISO 22716. It requires that a Responsible Person be able to answer questions from authorities and supply documentation. None of that is possible on a consistent basis without a structured QMS.

The second reason is risk reduction. Cosmetic products pose risks that are different from pharmaceuticals, but they are not negligible. Poorly preserved products can support microbial growth. Inadequate cleaning or cross-contamination can lead to unwanted ingredients ending up in products where they do not belong. Allergen or sensitizer levels can be higher than intended if suppliers are not controlled or formulas drift. Labels can omit required warnings or misstate net contents. Claims can suggest uses that shift the product into a medicinal or drug category without supporting data. These risks are amplified when companies work with multiple contract manufacturers, outsource certain processes, or change suppliers frequently.

The QMS helps identify where those risks arise, evaluate their impact, and put controls in place. It enforces systematic review of raw materials. It drives qualification and oversight of suppliers. It standardizes cleaning and hygiene practices. It requires that labels be reviewed not just for brand consistency but for regulatory content. It sets expectations for how potential safety issues are triaged and escalated.

The third reason is efficiency. Manual ways of working often look fast at the surface because people can “just make it work” with emails, calls, and spreadsheets. Over time, that speed is an illusion. Without a QMS, batches spend longer waiting for someone to review paper records. Artwork changes bounce between inboxes without clear ownership or cut-off dates. Ingredient changes get implemented inconsistently between sites. Complaints pile up because no one has a structured process for evaluating and closing them. Investigations drag out because data is hard to assemble.

A QMS organizes these flows. It formalizes who is involved in which decisions, in what order, and with which inputs. It reduces rework caused by unclear expectations. It supports faster batch release because records are structured and complete. It allows artwork to move through a defined process rather than getting stuck in loops. It makes it easier to train replacements when roles change because the process is not stored only in one person’s head.

The fourth reason is traceability. When a retailer raises a concern about a batch, when a regulator investigates a pattern of complaints, or when an internal team discovers a problem with a raw material, you need to be able to answer basic questions quickly and accurately. Which products used that material? Which lots are affected? Which markets received them? What tests were performed? What were the results? Who approved the product for release? What cleaning was done before that production run?

Without a QMS, these questions require manual reconstruction. In some cases, they cannot be answered at all. That lack of traceability intensifies regulatory, legal, and reputational risk. A structured QMS builds traceability into daily work so that the answers exist before the questions are asked.

The fifth reason is continuous improvement. Cosmetics is a fast-moving industry. New product trends, new ingredients, and new claims appear constantly. Regulations change. Retailers tighten requirements. Consumers react strongly to perceived issues or negative publicity. A company needs more than the ability to stay out of trouble. It needs the ability to see patterns in its own performance and adapt.

A QMS supports that by turning individual incidents into data. Deviations, complaints, and nonconformances are not just closed and forgotten. They are coded, trended, and discussed. Audit findings are not just resolved one by one. They are analyzed for systemic weaknesses. Supplier performance is tracked over time. Training data shows where turnover or change in procedures is creating gaps.

This allows management to identify where investments in process, equipment, or people will have the greatest effect. It also allows the company to validate whether those investments worked. Without a QMS, improvement is guesswork.

In short, a cosmetics QMS matters because regulators expect it, because it reduces real risks, because it makes operations more reliable, because it creates traceability, and because it enables improvement instead of repetitive firefighting.

Cosmetics Quality Standards, Guidelines, and Regulations

A cosmetics QMS does not exist in a vacuum. It is shaped by a network of regulations and standards that define what “acceptable” looks like. While each region has its own laws, certain reference points are widely recognized and influence how companies structure their systems.

In the United States, MoCRA has shifted expectations. It requires companies to ensure they have records that substantiate the safety of each cosmetic product. That includes data on ingredients and finished products, toxicological profiles, and other relevant information. It requires facilities to register with FDA and products to be listed, which forces companies to have accurate, up-to-date product data at hand. It requires reporting of serious adverse events associated with cosmetic products, which means companies must have a clear process for identifying, classifying, and tracking such events. Finally, it creates a path for FDA to establish GMP regulations specifically for cosmetics, which will formalize expectations around documentation, training, cleaning, and process control.

In the European Union, the Cosmetics Regulation sets a more established structure. Each product must have a Product Information File available to authorities at the address of the Responsible Person. That file must contain, among other things, a detailed cosmetic product safety report, a description of the product, the manufacturing method, evidence of the effect claimed when relevant, and data on animal testing where applicable. The regulation expects that products are manufactured according to Good Manufacturing Practice. ISO 22716 is the reference standard for GMP in cosmetics and describes in detail what authorities expect to see in terms of organization, personnel, premises, equipment, raw materials, production, finished products, quality control, waste, complaints, and recalls.

Other jurisdictions have their own equivalents. The United Kingdom has retained many EU principles in its own cosmetics regulations. Canada requires notification of cosmetics and sets out requirements for labeling and safety. Many other countries have adopted frameworks that draw on EU, US, or ISO references, especially where products are imported or brands operate across borders.

Retailers also act as de facto regulators. Large chains have their own quality and safety standards, often stricter than baseline regulations. They may require documentation of GMP certification, access to safety assessments, completion of questionnaires, or the ability to pass third-party audits. They may ban certain ingredients as a condition of listing or require specific claims or warnings on packages. For many brands, meeting retailer standards is just as important as meeting legal minimums.

All of these expectations influence the QMS. The system must be able to:

- Produce the documentation required to support product safety in each market.

- Demonstrate that products are manufactured under controlled, documented processes that align with GMP guidance.

- Show how the company monitors and manages post-market safety through complaints and adverse event reports.

- Provide authorities and customers with the information they require during inspections or audits.

The QMS also has to remain flexible enough to adapt as regulations change. For example, as FDA finalizes GMP rules for cosmetics or as the EU updates annexes that restrict certain substances, the QMS needs to support impact assessment, controlled changes, and retraining of staff. It must make it possible to identify all products affected by a regulatory change and to plan and track the necessary updates.

Documentation Structure of a Cosmetics QMS

When a regulator or auditor looks at a cosmetics company’s QMS, one of the first things they ask is how the system is structured. They want to see that the company has a clear hierarchy of documents that explains what it does, how it does it, and how it captures that work.

At the top of that hierarchy sits the quality policy. This is a short statement from leadership that defines the company’s commitment to product safety, regulatory compliance, and continuous improvement. It signals that quality is not a narrow function. It is an organizational priority.

Below the policy comes the quality manual or equivalent document. The manual describes the scope of the QMS, the processes it covers, the roles and responsibilities involved, and the way the system maps to regulatory expectations and standards such as ISO 22716. It explains how product safety assessment, GMP, labeling control, and post-market monitoring fit together. It often includes a high-level process map, showing how information flows between development, operations, quality, regulatory, and other functions.

Supporting the manual are policies on specific topics such as product safety, supplier management, complaint and adverse event handling, CAPA, data integrity, and document control. These policies state what the company intends to do. They define principles rather than detailed steps.

At the level below that sit standard operating procedures. SOPs describe how the company executes key processes. For example, one SOP may cover how new suppliers are evaluated, approved, and periodically re-evaluated. Another may cover how batches are manufactured and documented. Another may describe the process for handling deviations, from initial detection to investigation and closure. There will be SOPs for cleaning equipment, controlling environmental conditions where relevant, handling raw material receipt and testing, performing microbiological testing, assigning shelf life, handling complaints, and conducting internal audits and recalls.

Work instructions and job aids exist where tasks require more detailed description than is appropriate for an SOP. For instance, there may be a work instruction that describes step-by-step how to set up and clean a particular filling machine, including diagrams and pictures. Another might explain how to perform a specific microbial test, from sample collection through plating and incubation. These documents support consistency at the level of individual actions.

Forms and templates tie processes together by standardizing how information is recorded. A batch record template, for example, outlines which data must be captured during manufacturing and filling, including ingredient lot numbers, processing parameters, in-process checks, and approvals. A complaint form standardizes which details are collected from consumers or customers. A CAPA form guides staff through problem description, root cause analysis, action planning, and effectiveness verification. Artwork approval forms ensure that all required functions sign off before a label goes live.

Finally, records sit at the bottom of the hierarchy. Records are the completed batch documents, the signed cleaning logs, the test reports, the training completion records, the executed complaint investigations, the CAPA files, and the management review minutes. These are not instructions; they are evidence. Records must be retained, protected, and retrievable. They must be legible, attributable to individuals, and dated.

In a paper environment, maintaining this hierarchy is a constant effort. Documents need to be printed and distributed. Old versions must be collected and destroyed or clearly marked obsolete. Records must be filed and protected from damage. Staff must know which binder or cabinet holds which information. In an electronic environment, the same principles apply, but they are enforced through version control, electronic signatures, access control, and electronic archives.

Regardless of the medium, what matters is that the documentation structure is clear, controlled, and aligned with how the company actually works. If daily practice does not match what is written, or if records cannot be located or do not exist, the QMS may look good on paper but will fail under inspection.

Core Processes in a Cosmetics QMS

A QMS is not judged only by its documents. It is judged by how well it controls the processes that matter for quality and safety. In cosmetics, several processes are consistently critical in the eyes of regulators and customers.

One core process is product development and safety assessment. Before a product goes to market, someone has to define what it is, where it will be sold, what claims will be made, which consumers it targets, and what conditions of use are expected. Based on that, the formulation team selects ingredients, sets specifications, and defines the manufacturing process. The safety assessment process then compiles data on the ingredients, including their toxicological profiles, restrictions in relevant regulations, and known sensitization or irritation potential. It considers the intended use, amount of product applied, contact area, and frequency of use. A qualified safety assessor documents the conclusion. The QMS must define how these steps are done, who is responsible, how decisions are documented, and how updates are handled if the formula or claims change.

A second core process is supplier and raw material management. Most cosmetics companies do not control every part of their supply chain. They rely on external suppliers for chemicals, pigments, fragrances, packaging components, and contract manufacturing. The QMS must define how suppliers are selected, what criteria they must meet, what information they must provide, and how they are monitored over time. It must describe how incoming raw materials are received, identified, sampled, tested, and released for use. It must define what happens if a material fails testing or arrives with incomplete or inconsistent documentation. This process is central because poor control upstream is often the source of problems downstream.

A third key process is manufacturing and filling. This includes all steps from weighing and combining ingredients through mixing, heating or cooling when needed, transfer of bulk to filling lines, filling into primary packaging, and application of secondary packaging and labels. The QMS sets standards for cleanliness of equipment and areas, hygiene of personnel, sequencing of batches on lines, line clearance between different products, and process parameters such as temperatures, mixing times, and speeds. It defines what in-process checks must be done and what acceptance limits apply. It clarifies what must be recorded in batch records and who signs off at each stage.

Cleaning and sanitation form a process of their own. Cosmetic products often involve water-based systems and packaging that consumers will open and close. If cleaning is weak, residues can contaminate subsequent products, and microbes can find niches in lines and tanks. The QMS specifies what cleaning agents are used, how often equipment and spaces are cleaned, how cleaning effectiveness is verified, and how cleaning records are maintained. It addresses how cleaning procedures change when a product category changes or when there is a known contamination event.

Laboratory control is another essential process. In cosmetics, this often means microbiological testing, stability testing, and basic physical-chemical checks. The QMS defines how samples are taken, which tests are performed by batch or by product type, what methods are used, and what acceptance criteria apply. It sets expectations for handling out-of-specification results, including confirmatory testing, investigation, and impact assessment on previously released products.

Deviation and nonconformance management is a process that reveals how the company responds when things do not go as planned. The QMS must require that deviations from procedures, unexpected events during manufacturing, test failures, and label mix-ups are documented. It must describe how the significance of an event is assessed, how investigations are conducted, who must be involved, and how conclusions are reached. It must link deviations to decisions on rework, rejection, or use-as-is, and to CAPA where needed.

Complaint and adverse event handling extends the QMS into the market. Consumers, healthcare professionals, retailers, and others may report dissatisfaction, product defects, or health complaints. The QMS defines how these reports are collected, what information is captured, how seriousness is assessed, and how reports are investigated. It clarifies when a report is considered a serious adverse event under local law and how such events are reported to authorities. It ensures that complaints feed back into risk assessment, product development, and supplier oversight.

CAPA is the process that pulls together information from deviations, complaints, audits, and trend analysis. The QMS describes how issues are selected for CAPA, how root cause analysis is carried out, what kinds of actions are appropriate, and how implementation and effectiveness are checked. CAPA is the main vehicle for systemic improvement. If it is weak or superficial, problems tend to recur.

Change control is another central process. Formulas change, suppliers change, equipment changes, labels change, and processes are optimized. The QMS must ensure that any change with potential impact on quality, safety, or regulatory status is formally proposed, assessed, approved, implemented, and documented. It must require that impact on stability, micro performance, safety assessment, labeling, and regulatory filings is considered. It must link changes to updated documentation and training.

Artwork and labeling control is specific but critical in cosmetics. Labels must list ingredients, provide warnings where required, display product identity and net contents, and identify the responsible party. Claims on labels and packaging can shift a product into a different regulatory category if not managed carefully. The QMS defines how new artwork is created and reviewed, who approves it, how final files are controlled, and how labels applied on lines are matched to approved versions. It describes how changes in regulations or in formula composition trigger updates to labels.

Training and competency management ensures that people can execute all of these processes. The QMS links each role to the procedures and instructions that must be understood. It describes how training is delivered, how comprehension is evaluated, and how training records are kept. It clarifies what happens when procedures change and retraining is needed.

Audit management and management review are the processes that check whether the QMS itself is working. Internal audits assess whether procedures are followed and whether they are effective. Supplier audits evaluate external partners. Management review sessions bring together data from all processes so leadership can see the overall state of quality and safety.

All of these processes operate together. Deviation management connects to CAPA, which connects to change control, which connects to training, which connects back to execution on the line. The QMS exists to make those connections explicit and reliable.

Types of Cosmetics QMS Solutions

How a company implements its QMS depends on its history, size, and resources. Across the industry, several patterns are common.

Some companies still rely on fully manual systems. They keep SOPs and work instructions in printed binders. They use paper forms for deviations and complaints. They ask operators to sign paper training records. They file batch records and test reports in cabinets. These companies may meet some regulatory expectations, but they pay a price in time and risk. It takes longer to retrieve documents during audits. It is harder to keep everyone working with the current version of a procedure. Trending and analysis require manual data entry or review. When volumes increase, manual systems strain.

Others use hybrid systems. They store procedures and templates on shared drives or in a basic document management tool, but they still handle many processes, such as deviations, training, and CAPA, through email and spreadsheets. Artwork is approved by attaching files to email threads and collecting comments. Complaints are tracked in simple lists. Hybrid systems can feel more modern than paper, but they often duplicate the weaknesses of manual systems in digital form. They lack comprehensive audit trails. They rely on individual discipline to keep lists updated. They make it easy for different versions of the same document to circulate. They are hard to scale across multiple sites and partners.

Larger or older organizations may have legacy on-premises QMS tools. These systems centralize some functions, such as document control and deviations, but they run on internal servers and require significant IT effort to maintain. They may have been heavily customized to fit previous needs. Over time, they can become brittle. Upgrading them can be complex. Integrating them with other systems, such as lab systems, enterprise resource planning tools, or external partner systems, can be expensive. User interfaces may be less intuitive, which affects adoption.

In contrast, cloud-based QMS platforms are designed to provide a central, configurable environment accessible from different locations. They usually include modules for document management, training, deviations, CAPA, complaints, change control, supplier management, and audits. They enforce version control and electronic signatures. They maintain audit trails of who did what and when. They make it possible to create dashboards and reports that show the state of quality and safety across the organization. Because the software is hosted externally, internal IT teams have a lighter load. Updates can be deployed more frequently and more easily, subject to validation needs.

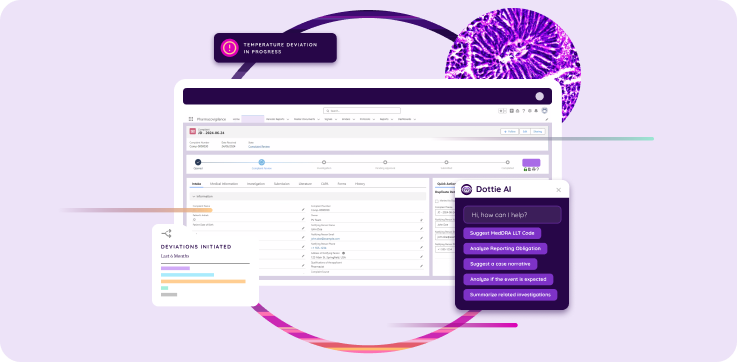

The most advanced systems are now adding AI capabilities within a governed environment. Instead of leaving staff to manually search through thousands of documents or records, these systems can answer questions like “which products use this ingredient?” or “which complaints in the last year mention eye irritation?” by searching structured and unstructured data in the QMS. They can highlight patterns that may not be obvious, such as a rise in deviations involving a particular packaging line or a concentration of complaints linked to one manufacturing site. They can support investigations by pointing users to similar past issues and the actions that resolved them.

However, AI used in quality and regulatory contexts must be deployed carefully. It has to operate within the QMS, not as an external tool that generates information with no connection to controlled records. Outputs must be traceable. Users must remain responsible for decisions. The QMS remains the system of record; AI is an assistant within that system.

The choice of QMS solution influences how easily a cosmetics company can meet existing regulations, adapt to changes, manage growth, and collaborate with partners. Manual and hybrid systems can work for small, simple operations. As soon as complexity increases, the case for a structured, electronic, and eventually AI-assisted QMS becomes strong.

How a Cosmetics QMS Supports Inspections and Continuous Improvement

Inspections and audits are a reality for cosmetics companies. Regulators may visit facilities to review GMP practices, evaluate complaint handling, or examine product documentation. Retailers may perform their own audits before or during a commercial relationship. Internal audit teams may assess sites as part of corporate governance.

A cosmetics QMS changes the way a company experiences these events. In a weak system, inspections trigger panic. Teams scramble to locate documents, reconcile conflicting versions, fill gaps in records, and coach staff on how to answer questions. In a strong system, inspections are more a matter of showing how the company already operates.

During an inspection, authorities will often ask to see specific procedures and records. They may request the SOP that describes how equipment is cleaned in a given area and then ask to see actual cleaning records for a period. They may pick a batch number from a complaint and ask to see the full batch record, related test results, and any deviation reports. They may ask for the safety assessment of a product, along with evidence supporting its conclusions. They may review complaint and serious adverse event records and look at how decisions on reporting and recall were made.

An QMS makes these requests straightforward to handle. Procedures and records are organized and controlled. Staff know where to find them and which versions are current. Records are complete because the QMS has required them at the time of work. Audit trails show who approved documents and when.

Beyond inspections, the QMS is central to continuous improvement. It collects data on deviations, nonconformances, complaints, audits, and CAPA. That data can be analyzed to identify which processes are most fragile, which suppliers contribute most to nonconformances, which lines or shifts see more issues, and where training may be weak. It can show whether CAPA actions are effective or whether the same issues keep recurring under different forms.

For example, if micro failures are trending upward for a certain category of products, the QMS data can help show whether the failures are associated with a specific site, a specific line, a particular preservation system, or a particular packaging format. That insight can guide targeted investigations and changes. If label errors keep appearing, the QMS can show whether they tend to arise at the artwork design stage, at printing, or at line selection and application. That, in turn, can drive improvements in the artwork review process or in line clearance practices.

Management review is the point where these insights are brought together. A structured QMS defines what information must be presented at management review meetings, how often they occur, who attends, and how decisions and actions are recorded. That keeps leadership connected to the state of quality and safety and provides a forum where priorities are set.

Without a QMS, improvement efforts are ad hoc. Individual issues may be solved, but patterns are missed. Knowledge is lost when people leave. Resources are allocated based on anecdotes and short-term pressure rather than consistent data.

Why a Modern Cosmetics QMS Matters

Many cosmetics companies were able to grow for years without a formal QMS or with only a minimal one. That is changing. Regulatory expectations, retailer demands, and consumer scrutiny have all increased. At the same time, business models are more complex. Brands launch more product variants across more markets, work with more external partners, and operate in faster product cycles.

In that environment, a modern QMS is not just a regulatory requirement. It is a competitive necessity.

A modern QMS delivers control, visibility, and scalability in a way older approaches cannot.

A modern QMS delivers control and consistency by enforcing clear processes across locations and partners. It makes sure that documentation is current, that training is tied to roles and procedures, and that records exist where they are needed. It reduces variability from site to site. It reduces dependence on individual memory. It makes the company less vulnerable to turnover or organizational change.

It also provides visibility. Leaders can see, in one place, the status of critical activities. They can see how many open deviations exist, how many CAPAs are overdue, which suppliers are on watch, how many complaints have been received for specific products or categories, and how training completion looks across sites. They can see trends rather than relying on isolated reports.

A modern QMS also supports scale. When a brand adds a new product line, opens a new facility, or brings a new contract manufacturer online, the QMS provides a ready-made framework. New entities can adopt existing processes and templates instead of inventing their own. This speeds integration and reduces the risk of inconsistent practices. When regulations change or retailer requirements tighten, the company can implement updates through the QMS and track their adoption.

Finally, a modern QMS lays the foundation for the controlled use of new technologies, including AI. Without a structured system, AI will pull from unstructured, uncontrolled data and create additional risk. With a structured system, AI can help staff work faster, but the underlying quality and safety controls remain intact.

In a market where brand trust is fragile, the ability to demonstrate control, respond quickly to issues, and maintain consistency across products and markets is a real advantage. A modern cosmetics QMS is how companies build that ability.

The Role of AI in the Modern Cosmetics QMS

AI is now part of many business discussions, including in quality and regulatory functions. In cosmetics, the goal is not to let AI replace quality decisions. The goal is to use it within a controlled QMS to reduce friction and make better use of existing data.

Within a modern QMS, AI can assist with information retrieval. For example, when a safety assessor is reviewing a new formula, they may need to see all products that use a particular ingredient, the complaints associated with those products, and any deviations that have mentioned that ingredient. Instead of manually searching across multiple modules, they can ask the system to pull together that information. When a regulator asks for all complaints related to eye irritation for a specific product range, AI can help identify relevant records quickly.

AI can also assist with pattern recognition. Over time, the QMS will collect large amounts of data on deviations, complaints, test failures, and CAPA. AI tools can scan this data for patterns that might be missed in manual reviews. They might show that a certain packaging format sees more leakage complaints, that micro failures are more common in products made during specific months, or that certain types of issues cluster around particular suppliers.

In investigations, AI can help by pointing users to similar incidents that occurred in the past and how they were resolved. This can reduce the time it takes to assemble context and avoid repeating unsuccessful approaches. During audits, AI-powered search within the QMS can make it easier to retrieve documents and records by interpreting questions and mapping them to the right data.

To be acceptable in a regulated, inspection-facing environment, AI must be governed. It must not change records or create official documents on its own. It must operate on top of controlled data rather than replacing it. Every query and response that matters must be traceable. Users must remain accountable for decisions. AI should be a tool for quality professionals, not a separate system that creates new obligations and uncertainties.

In that sense, the role of AI is to increase the value of an already strong QMS. It does not remove the need for structure. It makes that structure easier to navigate and use.

Frequently Asked Questions (FAQs): Cosmetics QMS

What is a cosmetics Quality Management System (QMS)?

A Cosmetics Quality Management System is the framework a cosmetics company uses to plan, carry out, document, review, and improve all activities that affect product quality and consumer safety. It connects product development, raw material sourcing, manufacturing, cleaning, filling, labeling, testing, storage, distribution, complaints, and corrective actions into one controlled system. The QMS defines how work is done, ensures people follow those methods, and captures records that prove what happened.

Why does a cosmetics QMS matter for brands?

A cosmetics QMS matters because regulators, retailers, and consumers expect proof that products are safe and made under control. It is how companies demonstrate compliance with requirements like MoCRA in the U.S. and the EU Cosmetics Regulation, manage risks in formulas and processes, maintain traceability from raw materials to finished goods, and avoid repeated firefighting. A functioning QMS also supports more reliable production, faster release decisions, and better responses when issues arise.

Is a cosmetics QMS legally required?

Regulations do not always use the exact phrase “quality management system,” but they expect what a QMS delivers. MoCRA in the U.S. requires safety substantiation, serious adverse event reporting, and GMP requirements that will be formalized by FDA. The EU Cosmetics Regulation requires manufacturing under Good Manufacturing Practice (typically aligned with ISO 22716) and a Product Information File for each product. Without a structured QMS, it is very difficult to meet these expectations consistently or to supply the documentation regulators and retailers ask for.

How does a cosmetics QMS relate to GMP and ISO 22716?

Good Manufacturing Practice and ISO 22716 describe what “good” looks like in cosmetic production: controlled premises and equipment, trained personnel, defined processes, documented cleaning, raw material and finished product control, complaint handling, and recall processes. The QMS is how a company implements and maintains those expectations. It translates GMP principles into specific procedures, work instructions, records, and oversight mechanisms and ensures they are followed in daily operations.

What processes should a cosmetics QMS cover?

A cosmetics QMS should cover the full product lifecycle and the supporting systems around it. That includes product development and safety assessment, supplier and raw material management, manufacturing and filling, cleaning and sanitation, lab control (microbiology, stability, and physical testing), deviation and nonconformance management, complaint and adverse event handling, CAPA, change control, artwork and labeling governance, training and competence, internal and supplier audits, and management review. These processes must be connected so that events in one area drive action in others.

Do small brands and contract manufacturers really need a QMS?

Small brands and contract manufacturers face many of the same expectations as larger organizations, especially when they sell into regulated markets or supply major retailers. Even if the scope is narrower, they still need documented ways of working, traceable batch and cleaning records, structured complaint handling, and basic CAPA. A lighter-weight QMS may be enough at first, but as product lines, markets, and partners expand, an informal or purely manual approach becomes harder to defend and harder to scale.

How does an electronic QMS (eQMS) help cosmetics companies?

An electronic QMS centralizes key quality processes into one controlled environment. It enforces version control and electronic signatures for documents, standardizes how deviations, complaints, CAPA, and change controls are handled, links training to current procedures, and provides audit trails for regulators and customers. It also makes it easier to trend issues, monitor supplier performance, and prepare for inspections because records are searchable and connected instead of spread across binders, inboxes, and spreadsheets.

Bringing It All Together

Cosmetics companies are judged not only by how appealing their products look or how well they sell, but by how they manage the safety and quality of those products over time. Regulators, retailers, and consumers expect companies to know what they are doing, to be able to show how they are doing it, and to fix issues in a structured way when they arise.

The Cosmetics Quality Management System is how companies meet those expectations.

A QMS defines how work is done, ensures that work follows defined methods, captures records of what happened, reviews those records, and uses what it learns to prevent issues. It aligns product development, supplier management, manufacturing, labeling, complaint handling, and regulatory oversight. It provides a framework for complying with regulations like MoCRA and the EU Cosmetics Regulation and for meeting the practical demands of major retailers and partners.

Manual and hybrid systems can support this to a point, but they strain as complexity and scrutiny grow. Modern, cloud-based QMS platforms, increasingly supported by AI within a governed environment, offer a more sustainable way forward. They provide control, visibility, and scalability.

For cosmetics companies that want to stay on the market, expand into new regions, and maintain the trust of regulators, retailers, and consumers, investing in a mature QMS is less about “nice to have” and more about “necessary to operate.”