How Do I Migrate from a Legacy QMS to a Modern Platform?

Migrating from a legacy Quality Management System (QMS) to a modern platform is one of the most consequential decisions a regulated organization can make. In life sciences, the QMS is not just a system of record. It is the operating framework that connects compliance, quality, and risk across the product lifecycle. When that framework is outdated, fragmented, or no longer supported, the impact extends far beyond inefficiency. It affects audit readiness, data integrity, scalability, and ultimately patient safety.

Many organizations recognize the need to move away from legacy systems but delay action due to uncertainty.

Questions around data migration, validation, regulatory risk, and business disruption often stall progress. The result is continued reliance on systems that are costly to maintain, difficult to adapt, and increasingly misaligned with regulatory expectations and modern operating models.

This guide explains how to migrate from a legacy QMS to a modern platform in a controlled, compliant, and practical way. It outlines how to plan the transition, what data to move, how to validate the new system, and how to position your organization for long-term quality maturity.

Understanding What a Legacy QMS Really Is

A legacy QMS is not defined by age alone. It is defined by limitations. These systems are often on-premises or heavily customized environments that require constant IT involvement, extensive validation cycles, and manual workarounds. Even systems marketed as “cloud” may still operate like on-prem software, with rigid architectures and painful upgrades.

Over time, these platforms tend to accumulate complexity rather than clarity.

Quality data becomes fragmented across modules or external tools. Reporting is limited or static. Change management slows. User adoption declines. What once supported compliance gradually becomes a source of risk.

This is why migration is rarely driven by preference. It is driven by necessity.

Why Organizations Decide to Migrate

Organizations typically reach a tipping point where maintaining the legacy QMS carries more risk than replacing it. That moment may come when vendor support is reduced, regulatory expectations change, or the business expands beyond what the system can support.

Regulatory pressure plays a major role. FDA QMSR, EU MDR, Annex 11, and evolving global standards require stronger traceability, risk-based decision-making, and system-wide visibility.

Legacy platforms often struggle to meet these expectations without significant manual effort.

At the same time, operational realities have changed. Distributed teams, accelerated development cycles, and increased reliance on data-driven decision-making demand systems that are flexible, connected, and scalable. A modern QMS is designed to support this reality.

What Defines a Modern QMS

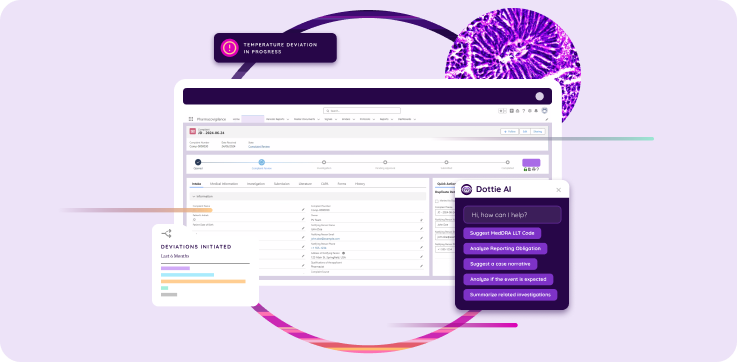

A modern QMS is not simply a digitized version of paper processes. It is a cloud-native platform designed to unify quality operations across the organization. Rather than relying on heavy customization, modern systems use configuration to adapt workflows while preserving validation and compliance.

These platforms centralize data across documents, training, deviations, CAPAs, change control, audits, suppliers, and risk.

They support real-time reporting, controlled access, electronic signatures, and audit trails by design. Importantly, they are built to evolve without requiring revalidation at every update.

This architectural shift is what makes migration worthwhile.

Defining the Scope of the Migration

One of the most common mistakes organizations make is assuming that everything must move at once. A successful migration starts with defining scope intentionally.

The first question is not what can be migrated, but what must be live immediately to maintain compliance and business continuity. Core processes such as document control, training, deviations, CAPA, and change control are typically prioritized. Other areas can be phased in once the foundation is stable.

Equally important is deciding what historical data truly needs to be migrated. Not all legacy records need to live in the new system to remain compliant. Regulators care about accessibility, integrity, and retention—not physical location.

Assessing and Rationalizing Legacy Data

Before any data moves, it must be understood. This is often where organizations uncover hidden complexity.

Legacy systems frequently contain outdated records, incomplete workflows, duplicate entries, and inconsistent structures.

A thorough data assessment allows teams to separate what is still relevant from what can be archived. Active records, current SOPs, open deviations, and in-progress CAPAs typically need to be migrated. Older, closed records may be better retained in a controlled archive rather than imported into the new platform.

This step reduces risk, simplifies validation, and prevents legacy issues from being carried forward.

Designing the Future-State QMS

Migration should not be an exercise in recreating the past. Before data is moved, organizations should design how quality processes will operate in the new system.

Modern QMS platforms enable standardized workflows, automated training triggers, and tighter process integration. Designing these workflows upfront ensures that migrated data lands in a system optimized for current and future needs, not historical constraints.

This is also where role-based access, approval paths, and reporting requirements are defined. Done correctly, this step transforms migration from a technical project into an operational improvement initiative.

Executing Data Migration in a Controlled Way

With scope defined, data assessed, and workflows designed, migration can begin. In regulated environments, data migration must be deliberate and well documented.

Records are mapped from the legacy system to the new platform, cleaned as needed, and migrated through test environments before production.

User acceptance testing confirms that records are accessible, complete, and traceable. Final migration is typically accompanied by a controlled freeze of the legacy system to prevent gaps.

Every step is documented. This documentation becomes part of the validation package and supports audit readiness.

Validating the Modern QMS

Validation is often cited as the biggest barrier to migration, but modern platforms significantly reduce the burden compared to legacy systems.

Rather than validating infrastructure repeatedly, organizations validate intended use. Vendors provide validation documentation, templates, and pre-validated environments that align with regulatory expectations. Continuous validation models allow systems to evolve without restarting the process from scratch.

The result is a validated system that supports change rather than resists it.

Training Users and Driving Adoption

Technology alone does not improve quality. Adoption does.

Training should be role-based and embedded into the QMS itself.

Modern systems automatically assign training when documents change, roles are updated, or new processes are introduced.

This reinforces compliance while reducing administrative overhead.

Early involvement of quality, regulatory, and operational teams builds trust and accelerates adoption. When users see how the new system simplifies their work, resistance fades quickly.

Going Live and Moving Forward

Go-live is a milestone, not the finish line. A controlled cutover ensures continuity, with clear communication, support resources, and escalation paths in place.

Once the system is stable, organizations can expand functionality, integrate with other enterprise platforms, and introduce advanced analytics or AI capabilities.

The QMS becomes a foundation for continuous improvement rather than a static compliance tool.

Final Perspective

Migrating from a legacy QMS to a modern platform is not just a system upgrade. It is a strategic shift in how quality operates across the organization.

When done thoughtfully, migration reduces risk, improves visibility, supports compliance, and enables scale.

More importantly, it positions quality as an active driver of performance rather than a reactive control function.

A modern QMS is not about replacing software. It is about future-proofing quality.Still running a legacy QMS?

Download the white paper and see how to move forward.