Which Features Matter Most When Choosing an eQMS?

Selecting an electronic Quality Management System (eQMS) is one of the most critical technology decisions a company in a regulated industry can make. It’s more than just replacing paper binders with digital files; it’s an investment in a central infrastructure that impacts product quality, operational efficiency, regulatory compliance, and speed to market.

With a crowded market of solutions, it can be challenging to distinguish essential capabilities from optional add-ons. This guide breaks down the most important eQMS features, dividing them into two categories: foundational “must-haves” for compliance and strategic “differentiators” that drive business value.

The Essentials: Core Capabilities

These are the non-negotiable modules that are critical in any eQMS intended for regulated environments like life sciences or manufacturing. Without these, maintaining a state of control and audit-readiness is nearly impossible.

Document Control and Management

- What It Is: A centralized, secure repository for all controlled documents, including Standard Operating Procedures (SOPs), work instructions, policies, and specifications.

- Why It Matters: This is the heart of a QMS. It ensures that employees always access the most current, approved version of a procedure, eliminating the significant compliance risk of using outdated information.

- Key Capabilities to Look For:

- Automated version control with a complete, traceable revision history.

- Secure, role-based access to limit viewing and editing permissions.

- Automated review and approval workflows with 21 CFR Part 11-compliant electronic signatures.

- Watermarking and controlled printing to prevent unauthorized circulation.

Corrective and Preventive Action (CAPA) Management

- What It Is: A structured system for identifying, investigating, and resolving quality issues to prevent their recurrence.

- Why It Matters: FDA inspectors focus heavily on CAPA processes. A CAPA module demonstrates that your organization has a systematic approach to problem-solving and continuous improvement, rather than just fixing isolated issues.

- Key Capabilities to Look For:

- Configurable workflows for the entire CAPA lifecycle, from initiation to effectiveness checks.

- Integration with other QMS modules (e.g., a complaint or audit finding can automatically trigger a CAPA).

- Root cause analysis tools.

- Automated tracking of timelines and owner assignments.

Training Management

- What It Is: A system for assigning, tracking, and documenting employee training and qualifications.

- Why It Matters: Regulators require proof that personnel are qualified for their roles and trained on the latest procedures. An integrated training module connects training requirements directly to the documents people need to read, closing the loop between a procedure update and employee awareness.

- Key Capabilities to Look For:

- Role-based training matrices that automatically assign tasks.

- Linkage to the Document Control module for automatic retraining when an SOP is updated.

- Electronic training records and completion certificates.

- Dashboards for tracking completion status and identifying overdue training.

Audit Management

- What It Is: A toolset for planning, executing, documenting, and tracking internal, supplier, and regulatory audits.

- Why It Matters: This module helps you turn audits from a reactive scramble into a proactive process. It provides a single source of truth for all audit-related activities, from scheduling to finding-related CAPAs, demonstrating a culture of internal oversight to regulators.

- Key Capabilities to Look For:

- Audit planning and scheduling features.

- Digital checklists and templates.

- Tools for capturing findings and observations in real-time.

- Direct integration with the CAPA module to manage follow-up actions.

Change Control

- What It Is: A formalized process for proposing, evaluating, and implementing any changes to processes, systems, or documents.

- Why It Matters: Uncontrolled changes are a major source of compliance failures. A Change Control module ensures that every change is properly justified, risk-assessed, and approved before it goes live, maintaining a validated state of control.

- Key Capabilities to Look For:

- Standardized change request forms and workflows.

- Tools for impact and risk assessment.

- Traceability that links a change to related documents, training updates, and CAPAs.

The Differentiators: Features for Strategic Advantage

Once the foundational needs are met, these features separate a basic eQMS from a truly modern platform that can provide a competitive advantage.

Integrated Risk Management

- What It Is: The ability to embed risk assessment and mitigation directly into all other quality processes (like Change Control, CAPAs, and Supplier Management).

- Why It Matters: Modern regulations (like ISO 13485:2016) emphasize a risk-based approach. Instead of being a separate activity, risk management becomes the lens through which all quality decisions are made, allowing you to focus resources on the most critical issues.

- Key Capabilities to Look For:

- Configurable risk matrices and scoring tools.

- The ability to link risk assessments directly to specific changes, products, or processes.

- Integration that allows risk levels to trigger different workflows or approval requirements.

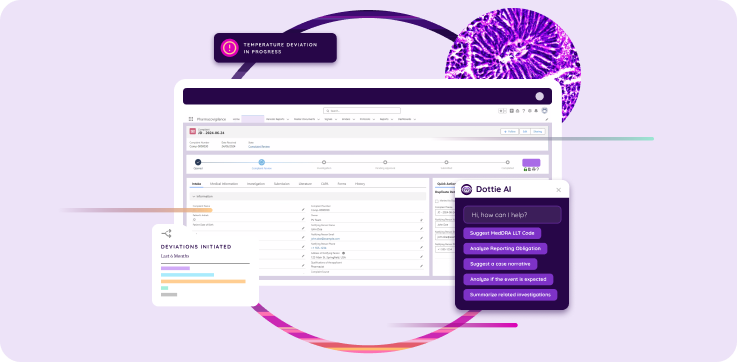

Analytics and Real-Time Dashboards

- What It Is: Visual, configurable dashboards and reporting tools that provide instant insight into quality Key Performance Indicators (KPIs).

- Why It Matters: Data-driven decision-making is impossible when quality data is trapped in spreadsheets or paper forms. Real-time analytics allow management to spot negative trends (e.g., rising deviations, overdue CAPAs) and act proactively, long before they become audit findings.

- Key Capabilities to Look For:

- Role-based dashboards that show relevant KPIs for each user.

- The ability to drill down from a chart into the specific records.

- Automated report generation for management reviews.

Platform and Integration Capabilities

- What It Is: The underlying technology of the eQMS and its ability to connect with other business systems like ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), or MES (Manufacturing Execution System).

- Why It Matters: A QMS should not be an information silo. A system built on a modern, scalable platform (e.g., a cloud-native platform like Salesforce) that offers APIs ensures data consistency across the organization and reduces manual data entry.

- Key Capabilities to Look For:

- Built on a secure, reliable, and scalable cloud platform.

- Well-documented APIs for integration.

- Pre-validated or validation-ready packages to speed up deployment.

User Experience (UX)

- What It Is: The overall ease-of-use, intuitiveness, and accessibility of the software interface.

- Why It Matters: A powerful eQMS is useless if no one uses it correctly. A poor user experience leads to low adoption, user frustration, and workarounds that defeat the purpose of the system. A clean, modern UX encourages engagement and ensures the QMS becomes part of the daily routine.

- Key Capabilities to Look For:

- A clean, uncluttered interface.

- Intuitive navigation.

- Mobile accessibility.

- Positive user reviews on sites like G2 or Capterra.

Prioritizing for Your Needs

Choosing the right eQMS requires looking beyond a simple checklist. While the foundational features are essential for compliance, the strategic differentiators are what will transform your quality department from a cost center into a value-driving engine. By understanding which features truly matter, you can select a system that not only helps you pass your next audit but also supports a lasting culture of quality and continuous improvement.

Need more guidance in selecting an eQMS? Download our white paper, “How to Choose the Right eQMS” and get actionable tips for streamlining your QMS selection process.