Can a QMS Really Help Reduce Time-to-Market for Regulated Products?

In regulated industries such as pharmaceuticals, biotechnology, and medical devices, bringing a product to market involves complex processes, strict documentation, and ongoing compliance oversight. Each stage, including development, validation, manufacturing, and post-market monitoring, requires clear evidence of quality and regulatory control. While quality management systems (QMS) are often seen as tools for compliance, they also play a direct role in reducing time-to-market by improving efficiency, visibility, and collaboration across the product lifecycle.

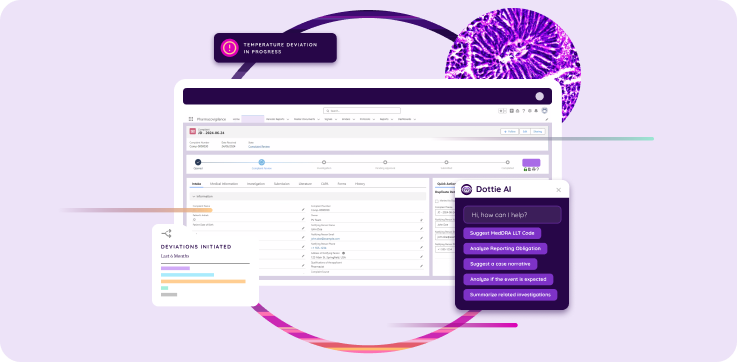

Connecting Processes and Information

An electronic Quality Management System (eQMS) centralizes critical quality processes such as document control, training, change management, and CAPA.

This connection eliminates silos between teams and ensures that data flows consistently across departments.

When teams use the same platform to review, approve, and track information, they avoid delays caused by missing documents or version errors. With automated routing and electronic signatures, approvals happen faster and in alignment with regulatory standards such as 21 CFR Part 11 and EU Annex 11. This efficiency helps organizations maintain compliance without slowing down development.

Streamlining Change and Risk Management

Change control is one of the most time-consuming processes in regulated environments. Each modification must be documented, assessed for impact, and approved by multiple stakeholders.

A QMS automates these steps, providing structured workflows that track every stage of a change request.

Automated notifications ensure that reviews happen on time and that risk assessments are completed before implementation. By linking change records to CAPAs, deviations, and validation documents, organizations create a closed-loop system that reduces rework and ensures traceability. This visibility shortens review cycles and helps teams implement improvements faster.

Accelerating Document Control and Training

Document control and training are critical in preparing for production and regulatory submissions.

A QMS automates version control and ensures that every team member accesses the most recent approved document.

When new procedures or specifications are released, the system automatically triggers training assignments based on user roles. Automated tracking confirms completion, reducing administrative work and the chance of oversight. With everyone trained and aligned faster, production and validation activities start sooner, directly supporting shorter timelines to market.

Improving Supplier and Production Readiness

Suppliers play a major role in regulated product development, from materials to contract manufacturing.

A QMS helps organizations qualify and monitor suppliers efficiently by tracking audits, certifications, and performance in one system.

Nonconformances can be linked to supplier records, creating a clear picture of risk and reliability. During scale-up and production, integrated processes such as equipment calibration, batch record review, and deviation management ensure that manufacturing readiness is achieved without unexpected delays.

Enhancing Regulatory and Audit Readiness

Regulatory submissions and audits often delay product launch when data is incomplete or difficult to trace.

A QMS maintains all records in an organized, audit-ready format with complete traceability from design to distribution.

Teams can quickly generate reports and respond to regulatory inquiries without manual document collection. This readiness minimizes disruptions during inspections and accelerates approval processes.

Accelerating Innovation Through Quality

A QMS does more than ensure compliance. It creates operational clarity that shortens the path from concept to commercialization. By automating key quality processes, enabling real-time visibility, and ensuring alignment across teams and suppliers, an eQMS reduces inefficiencies that traditionally slow regulated product development. The result is a faster, controlled, and compliant route to market that supports both innovation and patient safety.

Use our How to Choose an eQMS checklist to find the right system that accelerates compliance and time-to-market.